ISO 4650:2005

(Main)Rubber — Identification — Infrared spectrometric method

Rubber — Identification — Infrared spectrometric method

ISO 4650:2005 specifies a method for the identification of rubbers, including thermoplastic elastomers, either in the raw state or in the form of vulcanized or unvulcanized mixes. The method is based on infrared spectrometric examination using the transmission technique. The method comprises examination of polymers by their pyrolysis products (pyrolysates), or by films cast from solution or obtained by moulding (for raw rubbers only). Typical spectra are given.

Caoutchouc — Identification — Méthode spectrométrique dans l'infrarouge

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 4650

Second edition

2005-09-15

Rubber — Identification — Infrared

spectrometric method

Caoutchouc — Identification — Méthode spectrométrique dans

l'infrarouge

Reference number

ISO 4650:2005(E)

©

ISO 2005

---------------------- Page: 1 ----------------------

ISO 4650:2005(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2005

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2005 – All rights reserved

---------------------- Page: 2 ----------------------

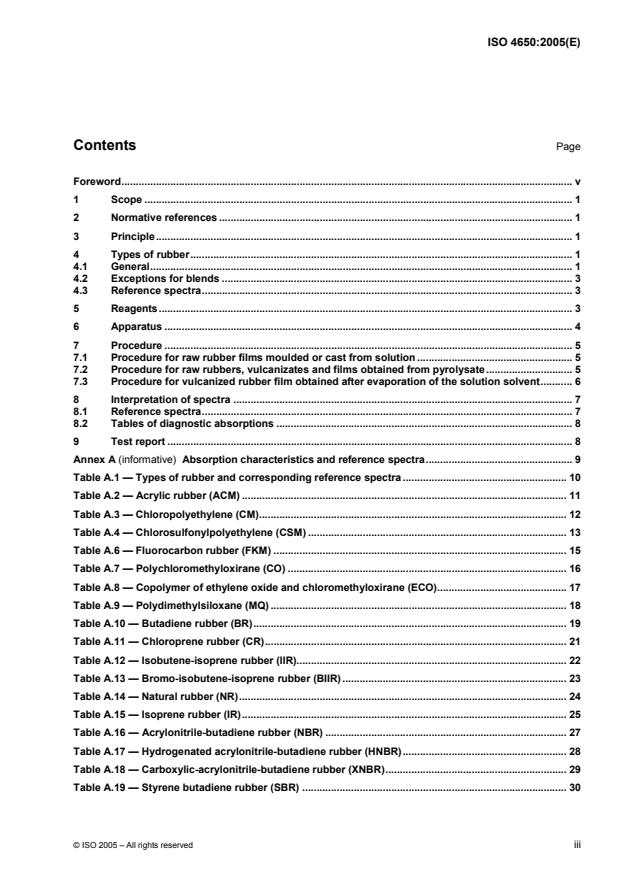

ISO 4650:2005(E)

Contents Page

Foreword. v

1 Scope . 1

2 Normative references . 1

3 Principle. 1

4 Types of rubber. 1

4.1 General. 1

4.2 Exceptions for blends . 3

4.3 Reference spectra. 3

5 Reagents. 3

6 Apparatus . 4

7 Procedure . 5

7.1 Procedure for raw rubber films moulded or cast from solution . 5

7.2 Procedure for raw rubbers, vulcanizates and films obtained from pyrolysate. 5

7.3 Procedure for vulcanized rubber film obtained after evaporation of the solution solvent. 6

8 Interpretation of spectra . 7

8.1 Reference spectra. 7

8.2 Tables of diagnostic absorptions . 8

9 Test report . 8

Annex A (informative) Absorption characteristics and reference spectra. 9

Table A.1 — Types of rubber and corresponding reference spectra . 10

Table A.2 — Acrylic rubber (ACM) . 11

Table A.3 — Chloropolyethylene (CM). 12

Table A.4 — Chlorosulfonylpolyethylene (CSM) . 13

Table A.6 — Fluorocarbon rubber (FKM) . 15

Table A.7 — Polychloromethyloxirane (CO) . 16

Table A.8 — Copolymer of ethylene oxide and chloromethyloxirane (ECO). 17

Table A.9 — Polydimethylsiloxane (MQ) . 18

Table A.10 — Butadiene rubber (BR). 19

Table A.11 — Chloroprene rubber (CR). 21

Table A.12 — Isobutene-isoprene rubber (IIR). 22

Table A.13 — Bromo-isobutene-isoprene rubber (BIIR). 23

Table A.14 — Natural rubber (NR). 24

Table A.15 — Isoprene rubber (IR). 25

Table A.16 — Acrylonitrile-butadiene rubber (NBR) . 27

Table A.17 — Hydrogenated acrylonitrile-butadiene rubber (HNBR). 28

Table A.18 — Carboxylic-acrylonitrile-butadiene rubber (XNBR). 29

Table A.19 — Styrene butadiene rubber (SBR) . 30

© ISO 2005 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 4650:2005(E)

Table A.21 — Block copolymer of styrene and butadiene (TPS-SBS). 34

Table A.22 — Polystyrene-poly(ethylene-butylene)-polystyrene (TPS-SEBS) . 35

Table A.23 — Block copolymer of styrene and isoprene (TPS-SIS) . 36

Table A.24 — Polystyrene-poly(ethylene-propylene)-polystyrene (TPS-SEPS) . 37

Table A.25 — Syndiotactic poly(1,2-butadiene) (TPZ). 38

Table A.26 — Copolyester TPE with a soft segment with ester and ether linkages (TPC-EE) . 39

Bibliography . 40

iv © ISO 2005 – All rights reserved

---------------------- Page: 4 ----------------------

ISO 4650:2005(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 4650 was prepared by Technical Committee ISO/TC 45, Rubber and rubber products, Subcommittee

SC 2, Testing and analysis.

This second edition cancels and replaces the first edition (ISO 4650:1984), which has been technically revised.

© ISO 2005 – All rights reserved v

---------------------- Page: 5 ----------------------

INTERNATIONAL STANDARD ISO 4650:2005(E)

Rubber — Identification — Infrared spectrometric method

1 Scope

This International Standard specifies a method for the identification of rubbers, including thermoplastic

elastomers, either in the raw state or in the form of vulcanized or unvulcanized mixes. The method is based on

infrared spectrometric examination using the transmission technique.

The method comprises examination of polymers by their pyrolysis products (pyrolysates), or by films cast from

solution or obtained by moulding (for raw rubbers only).

Typical spectra are given in Annex A.

The principle of the method implies that sample preparation and analysis of the infrared spectra are carried

out by experienced personnel and that the equipment used for the production of spectra is operated in

accordance with the manufacturer's instructions for optimum performance. Details of the operation of infrared

spectrometers are not included in this International Standard.

The method specified is a qualitative method only.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 1407, Rubber — Determination of solvent extract

ISO 18064, Thermoplastic elastomers — Nomenclature and abbreviated terms

3 Principle

The extractable material is first extracted from a test sample of the rubber and the rubber then prepared under

precise conditions for spectroscopy in the form of raw polymer film, vulcanizate pyrolysate or vulcanizate film.

The IR spectrum is recorded and then interpreted by comparison with a set of typical reference spectra.

4 Types of rubber

4.1 General

The method is applicable to rubbers in the raw state and, if compounded, in both the vulcanized and

unvulcanized states. It is applicable to the following types of rubber occurring either alone or in a binary

mixture when the proportion of the minor component is, in general, not less than 10 % to 20 % by mass of the

mixture (see, however, exceptions in 4.2).

© ISO 2005 – All rights reserved 1

---------------------- Page: 6 ----------------------

ISO 4650:2005(E)

4.1.1 M group

4.1.1.1 Acrylic rubber (ACM): Copolymer of ethyl acrylate (or other acrylates) and a small amount of a

monomer which facilitates vulcanization.

4.1.1.2 Chloropolyethylene (CM) and chlorosulfonylpolyethylene (CSM): The method will not

differentiate CM from CSM, and it will not differentiate between different types of CSM.

4.1.1.3 Ethylene-propylene copolymer (EPM) and ethylene-propylene-diene terpolymer (EPDM):

The method will not differentiate between the two types of polymer. However, examination of the spectrum

gives some information about the ethylene-to-propylene ratio.

4.1.1.4 Fluorocarbon rubber (FKM): Examination of the pyrolysate may give some information about

the different grades of fluorocarbon rubber present.

4.1.2 O group

4.1.2.1 Polychloromethyloxirane (CO): Copolymer of ethylene oxide and chloromethyloxirane (ECO)

and terpolymers. Examination of the pyrolysate will not differentiate between different types of CO.

4.1.3 Q group

4.1.3.1 Polydimethylsiloxane (MQ), polymethylphenylsiloxane (PMQ) and polymethyl-

fluorosiloxane (FMQ): Examination of the pyrolysate will differentiate PMQ from MQ.

4.1.4 R group

4.1.4.1 Butadiene rubber (BR): Examination of the pyrolysate will not differentiate between butadiene

rubbers having different isomer ratios. However, examination of a raw rubber film gives some information

about the isomer ratio.

4.1.4.2 Chloroprene rubber (CR): The method will not differentiate between the different types of CR.

4.1.4.3 Isobutene-isoprene rubber (IIR) and halogenated isobutene-isoprene rubbers (BIIR and

CIIR): Under the conditions used for the method, it is not possible to differentiate between IIR, BIIR, CIIR and

polyisobutene.

4.1.4.4 Natural rubber (NR) and synthetic isoprene rubber (IR): Natural rubber (1,4-cis-polyisoprene),

gutta percha, balata (1,4-trans-polyisoprene) and synthetic isoprene rubber, whatever their microstructure,

(1,4-cis, 1,4-trans or 3,4-) are included.

4.1.4.4.1 Examination of a rubber film will differentiate between 1,4-cis, 1,4-trans and 3,4-polyisoprenes; for

non-extracted rubbers, it will differentiate natural rubber from 1,4-cis synthetic isoprene rubber, and 1,4-trans

natural polyisoprenes from their synthetic counterparts. Examination of the pyrolysate film obtained from a

vulcanizate provides no information on the microstructure of the polyisoprene or its origin, whether natural or

synthetic.

4.1.4.5 Acrylonitrile-butadiene rubber (NBR): The method will differentiate carboxylic acrylonitrile-

butadiene rubbers (XNBRs) from hydrogenated acrylonitrile-butadiene rubbers (HNBRs). Associations of

butadiene copolymers and PVC are included. Examination of the pyrolysate film gives some information about

the acrylonitrile content.

4.1.4.6 Styrene-butadiene rubber (SBR): The method will differentiate α-methylstyrene-butadiene

rubbers from styrene-butadiene rubbers. Copolymers of styrene and butadiene, as well as of their substituted

derivatives (e.g. α-methylstyrene), are included. Examination of a pyrolysate will not differentiate emulsion-

polymerized rubbers from solution-polymerized rubbers. However, examination of a spectrum gives some

information about the monomer ratio.

2 © ISO 2005 – All rights reserved

---------------------- Page: 7 ----------------------

ISO 4650:2005(E)

4.1.4.7 Polynorbornene.

4.1.5 T group

4.1.5.1 Polysulfide rubbers.

4.1.6 U group

4.1.6.1 Polyester urethane (AU) and polyether urethane (EU): The method covers only millable

polyurethanes.

4.1.7 TPE group

4.1.7.1 As defined in ISO 18064.

4.2 Exceptions for blends

4.2.1 Analysis of a blend of ethylene-propylene rubber with other rubbers presents difficulties when its

ethylene-propylene content is below 40 %.

4.2.2 The method will not differentiate between blends of ethylene-propylene rubber with chlorinated

polyethylene and/or chloro-sulfonated polyethylene.

4.2.3 Analysis of a blend of natural and/or synthetic polyisoprene and chloroprene rubber may present

difficulties, and identification of the minor component may only be possible when the content is equal to or

greater than 30 % in the blend.

4.2.4 The method will not differentiate NBR from NBR/BR blends or NBR blends, nor will it differentiate

SBR from SBR/BR blends or SBR blends.

4.2.5 The presence of high quantities of sulfur in a vulcanizate may affect some characteristic bands.

4.2.6 The method will not differentiate NBR/PVC blends from blends of NBR with other halogenated

polymers or additives.

4.3 Reference spectra

–1 –1

Tables of absorption characteristics and reference spectra from 4 000 cm to 600 cm for typical rubbers

are given in Annex A.

5 Reagents

5.1 Nitrogen, in pressurized cylinders.

5.2 Extraction solvents, chosen to achieve maximum extraction (alternative solvents may be used on

condition that it can be shown that they do not interfere with the interpretation of the infrared spectrum):

5.2.1 Methanol.

5.2.2 Acetone.

5.3 Solvents for rubber dissolution and film preparation, water-free and free from residues (see

ISO 1407):

5.3.1 Chloroform.

© ISO 2005 – All rights reserved 3

---------------------- Page: 8 ----------------------

ISO 4650:2005(E)

5.3.2 1,2-dichlorobenzene.

5.4 Sodium sulfate, anhydrous.

5.5 Universal pH-indicator paper.

6 Apparatus

6.1 Extraction apparatus.

The apparatus specified in ISO 1407 is satisfactory.

6.2 Pyrolysis apparatus (see Figure 1), comprising a glass tube A having inward projections to prevent

the sample from falling to the bottom of the tube, and a lateral condenser tube. The tube A has a standard

ground-glass joint B that carries a small glass adductor tube. A collecting tube C is placed under the

condenser tube. A thermoregulated electric furnace D accommodates an aluminium block E with holes for one

or more tubes A.

Key

A glass tube for sample

B ground-glass joint

C collecting tube

D thermoregulated electric furnace

E aluminium block, bored to hold tubes

F thermocouple

Figure 1 — Temperature-controlled pyrolysis apparatus

4 © ISO 2005 – All rights reserved

---------------------- Page: 9 ----------------------

ISO 4650:2005(E)

6.3 Capillary pipettes.

6.4 Oven, capable of being maintained at 200 °C ± 5 °C.

6.5 Water bath.

6.6 Polished potassium bromide salt plates.

6.7 Filter aid, e.g. diatomaceous earth or similar.

6.8 Infrared spectrometer, of either the Fourier transform or dispersive type, with a wavenumber range of

–1 −1 –1

4 000 cm to 600 cm and a spectral resolution of 4 cm or higher.

7 Procedure

7.1 Procedure for raw rubber films moulded or cast from solution

7.1.1 Using a suitable solvent (see 5.2), extract the extractable material from a test sample of 2 g to 5 g in

accordance with the procedure given in ISO 1407.

7.1.2 Dissolve a sufficient amount of the extracted rubber in a suitable solvent (see 5.3), at room

temperature or under reflux, to give a concentrated solution.

7.1.3 Place a few drops of the concentrated solution on a potassium bromide salt plate (6.6) and allow the

solvent to evaporate.

7.1.4 Films of raw rubber of a suitable thickness may also be obtained by moulding.

–1 –1

7.1.5 Record the spectrum from 4 000 cm to 600 cm using the infrared spectrometer (6.8).

7.1.6 After recording the spectrum, verify that no solvent absorption bands are present and check that the

bands of the spectrum are neither off-scale nor too low. If these conditions are not met, repeat the preparation

procedure on a fresh test sample and record a new spectrum.

7.1.7 A test for halogens may be carried out as described in 7.2.1.4.

7.2 Procedure for raw rubbers, vulcanizates and films obtained from pyrolysate

NOTE The methods described in 7.2.1 and 7.2.2 may give different relative absorbances for the polymers in a given

blend.

7.2.1 Preferred method: Temperature-controlled pyrolysis in a stream of nitrogen

7.2.1.1 Extract a 2 g to 5 g test sample in accordance with the procedure given in ISO 1407.

7.2.1.2 Depending on the nature of the composition of the unknown vulcanizate and of the type of

apparatus used, place 0,5 g to 2 g of the extracted, dried test sample in the pyrolysis tube A (see Figure 1).

7.2.1.3 Introduce a small quantity of sodium sulfate in the collector tube C to absorb water formed in the

pyrolysis.

7.2.1.4 Carry out a test for halogen, for instance by placing a strip of moistened indicator paper (5.5)

across the mouth of the collecting tube. An acid colour, pH 1 to pH 2, indicates the presence of halogen.

Residues of halogenated additives present in the vulcanizate may cause interference. Other suitable halogen-

detection methods may also be used.

© ISO 2005 – All rights reserved 5

---------------------- Page: 10 ----------------------

ISO 4650:2005(E)

7.2.1.5 Bring the electric furnace D to 525 °C ± 50 °C and hold within this temperature range. This

temperature range is recommended to obtain rapid pyrolysis without excessive degradation or carbonization.

A temperature of 475 °C is advised, however, to obtain the maximum quantity of pyrolysate for NR, IR, BR,

SBR, IIR, BIIR and CIIR.

7.2.1.6 Pass a slow stream of nitrogen (5.1) through the pyrolysis tube A and introduce the tube

containing the prepared test sample into a hole in the aluminium block E. Nitrogen serves to displace air,

prevent oxidation and facilitate transfer of the pyrolysis products into the collecting tube C. Maintain the

3 3

nitrogen flow at 10 cm /min ± 2 cm /min.

7.2.1.7 Continue the heating to complete distillation, i.e. for about 15 min.

7.2.1.8 Place a few drops of the homogenized pyrolysate between two potassium bromide salt plates and

mount the cell in the infrared spectrometer. Run the spectrum immediately after pyrolysis to avoid oxidation.

–1 –1

7.2.1.9 Record the infrared spectrum from 4 000 cm to 600 cm , performing the same checks as

described in 7.1.6.

7.2.2 Alternative method: Gas flame pyrolysis

7.2.2.1 Rapid pyrolysis may be performed in a test tube in place of the procedures described in 7.2.1.2,

7.2.1.3, 7.2.1.5, 7.2.1.6 and 7.2.1.7.

7.3 Procedure for vulcanized rubber film obtained after evaporation of the solution solvent

NOTE The methods described in 7.3.1 and 7.3.2 may give different relative absorbances for the polymers in a given

blend. The films obtained by the method described in 7.3.2 may contain a higher proportion of the thermally less stable

polymer.

7.3.1 Dissolution of vulcanizate

7.3.1.1 Prepare a test sample of about 2 g (or 6 g if the presence of chloroprene rubber is suspected)

(see 7.3.1.2 and 7.3.1.3) and proceed with the extraction as described in ISO 1407.

7.3.1.2 Pyrolyse approximately 1 g of the prepared test sample and carry out a halogen test as described

in 7.2.1.4.

3

7.3.1.3 If no chloroprene rubber is present, place 1 g of the test sample prepared in 7.3.1.1 and 50 cm of

3

a solvent appropriate to the rubber type (see 5.3) (1,2-dichlorobenzene is suggested) in a 100 cm flask fitted

with a reflux condenser. If chloroprene rubber is present, place approximately 5 g of the test sample prepared

3 3

in 7.3.1.1 with 200 cm of solvent in a 500 cm flask fitted with a reflux condenser.

Heat the contents until the test sample has dissolved.

The time required for adequate dissolution varies depending on the rubber, e.g. 3 h to 4 h for NR; 12 h for CR.

To reduce the risk of altering the molecular structure of the rubber, do not exceed 12 h heating.

7.3.1.4 If the rubber does not contain carbon black, centrifuge to eliminate mineral fillers.

7.3.1.5 If the rubber contains carbon black, add 10 g to 20 g of filter aid (6.7) and filter through filter paper.

Should the filtrate contain carbon black, repeat the filtration with more filter aid.

NOTE Acrylonitrile-butadiene rubber (NBR) may be retained on the filter paper.

7.3.1.6 Concentrate the centrifuged or filtered solution to a small volume under a stream of nitrogen (5.1)

or reduced pressure.

7.3.1.7 Evaporate a few drops of the concentrated solution on a potassium bromide salt plate.

6 © ISO 2005 – All rights reserved

---------------------- Page: 11 ----------------------

ISO 4650:2005(E)

–1 –1

7.3.1.8 Record the infrared spectrum from 4 000 cm to 600 cm , performing the same checks as

described in 7.1.6.

7.3.2 Mild thermal degradation of vulcanizates

7.3.2.1 This technique shall not be used on blends which may contain chloroprene rubber.

7.3.2.2 Prepare a test sample of 2 g as described in 7.2.1.1

7.3.2.3 Place the prepared test sample in a test tube capped with glass wool and heat for about 10 min in

an oven (6.4) regulated at 200 °C ± 5 °C (a temperature of 180 °C is advised for NR, IR, BR, SBR, IIR, BIIR

and CIIR rubbers).

3

7.3.2.4 Allow the test sample to cool, transfer to a 100 cm flask fitted with a reflux condenser and add

3

50 cm of chloroform (5.3.1) to the flask. Place the flask in a hot water bath.

7.3.2.5 Allow the flask and contents to remain for about 30 min in the water bath, with the solvent

refluxing, to dissolve the degraded rubber.

7.3.2.6 Filter the mixture obtained in 7.3.2.5 through filter paper to remove any undissolved vulcanizate

and fillers. Should carbon black be released from the vulcanizate, add a small amount of filter aid (6.7) to the

solution before filtering.

7.3.2.7 When it is suspected that the filtrate obtained in 7.3.2.6 contains material other than rubber which

might interfere in the interpretation of the final spectrum, precipitate the polymer from the filtrate obtained in

7.3.2.6 using methanol. Filter off the recovered polymer and redissolve it in chloroform (5.3.1).

7.3.2.8 Evaporate a few drops of the chloroform solution on a potassium bromide salt plate (6.6) to give a

film thickness suitable for the production of an analytical spectrum.

–1 –1

7.3.2.9 Record the spectrum from 4 000 cm to 600 cm , performing the same checks as described in

7.1.6.

8 Interpretation of spectra

8.1 Reference spectra

8.1.1 Due to the existence of different spectral presentation modes, it may be necessary to prepare a set of

reference spectra on the same infrared spectrometer as is used to analyse the unknown samples.

8.1.2 Reference spectra shall be produced from test samples of known composition, following the

procedure used for unknown samples.

8.1.3 Spectra of mixtures are not given in Annex A because of the multiplicity of polymer combinations and

proportions. Each laboratory should prepare its own set from test samples of known composition.

8.1.4 Small, but unavoidable, variations in experimental conditions and instrument characteristics may give

rise to slight differences in spectra. Spectra produced at different times may not be identical in terms of peak

height and absorbance.

8.1.5 In all cases, spectra shall be interpreted bearing in mind the result of the test for halogen.

8.1.6 The comparison between test spectra and reference spectra shall take into account the wavenumbers

of the bands, how many bands are present, their relative intensity and their form. Any unexpected bands shall

also be interpreted. It is essential that all the bands be examined, irrespective of their number.

© ISO 2005 – All rights reserved 7

---------------------- Page: 12 ----------------------

ISO 4650:2005(E)

8.2 Tables of diagnostic absorptions

8.2.1 The tables of diagnostic absorption bands given in Annex A shall be used only in conjunction with

reference spectra. Their purpose is to indicate the principal absorption bands.

8.2.2 The tables complement the reference spectra by drawing attention to absorption bands which are

absent, permitting the elimination of certain rubbers when ambiguity could otherwise arise.

8.2.3 Diagnostic absorption bands are classified by increasing wavenumber. A diagnostic absorption band

is one whose features are recognized by an experienced analyst as being of significance in rubber

identification. These features, associated with certain compositional or structural characteristics of the

pyrolysates and films, are reproducible in the sense that they are not seriously influenced by moderate

variations in the conditions of pyrolysis or of dissolution.

9 Test report

The test report shall include the following particulars:

a) a reference to this International Standard;

b) all details required for the complete identification of the sample;

c) the method used;

d) identification of the rubber(s) in the sample;

e) the date of the test.

8 © ISO 2005 – All rights reserved

---------------------- Page: 13 ----------------------

ISO 4650:2005(E)

Annex A

(informative)

Absorption characteristics and reference spectra

A.1 General

A.1.1 This annex provides tables of absorption characteristics and figures showing reference spectra for

pyrolysates and films.

A.1.2 Comparisons between sample spectra and reference spectra will have to take into account the

position of the bands, how many there are, their relative intensity and their shape.

A.1.3 It is essential that all the bands in a spectrum be examined, with no restrictions on the zone which is

searched for characteristic bands.

A.2 Tables of absorption characteristics and figures showing reference spectra

A.2.1 In order to ease the task of the user of this International Standard, the scale chosen for the

presentation of the spectra is designed to show clearly the specific absorption bands.

A.2.2 Table A.1 indicates which figures correspond to the reference spectra for which types of rubber.

© ISO 2005 – All rights reserved 9

---------------------- Page: 14 ----------------------

ISO 4650:2005(E)

Table A.1 — Types of rubber and corresponding

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.