ISO/TR 12134:2010

(Main)Rubber — Estimation of uncertainty for test methods — Non-functional parameters

Rubber — Estimation of uncertainty for test methods — Non-functional parameters

ISO/TR 12134:2010 provides guidance to scientists, engineers and technicians, working in the field of rubber materials and products, to supplement ISO/IEC Guide 98‑3 and to provide additional guidance in situations where functional relationships between input quantities (such as temperature, strain rate and time) and derived output quantities (such as tensile strength and compression set) are unknown and where no other guidance is available. The Technical Report provides a summary of the classical approach that is taken in the preparation of uncertainty budgets and provides a list of selected test methods and, for each, an indication of the factors that will make a contribution to the uncertainty budget.It also discusses how “non-functional” factors can be taken into account in the classical approach.

Caoutchouc — Estimation de l'incertitude des méthodes d'essai — Paramètres non fonctionnels

General Information

Standards Content (Sample)

TECHNICAL ISO/TR

REPORT 12134

First edition

2010-02-15

Rubber — Estimation of uncertainty for

test methods — Non-functional

parameters

Caoutchouc — Estimation de l'incertitude des méthodes d'essai —

Paramètres non fonctionnels

Reference number

ISO/TR 12134:2010(E)

©

ISO 2010

---------------------- Page: 1 ----------------------

ISO/TR 12134:2010(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

COPYRIGHT PROTECTED DOCUMENT

© ISO 2010

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2010 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/TR 12134:2010(E)

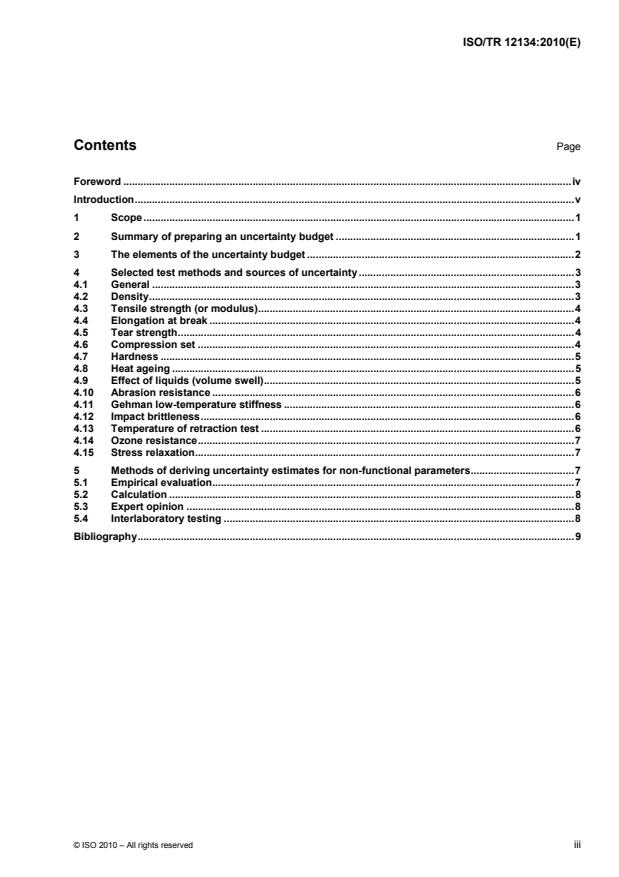

Contents Page

Foreword .iv

Introduction.v

1 Scope.1

2 Summary of preparing an uncertainty budget .1

3 The elements of the uncertainty budget .2

4 Selected test methods and sources of uncertainty.3

4.1 General .3

4.2 Density.3

4.3 Tensile strength (or modulus).4

4.4 Elongation at break .4

4.5 Tear strength.4

4.6 Compression set .4

4.7 Hardness .5

4.8 Heat ageing .5

4.9 Effect of liquids (volume swell).5

4.10 Abrasion resistance .6

4.11 Gehman low-temperature stiffness .6

4.12 Impact brittleness.6

4.13 Temperature of retraction test .6

4.14 Ozone resistance.7

4.15 Stress relaxation.7

5 Methods of deriving uncertainty estimates for non-functional parameters.7

5.1 Empirical evaluation.7

5.2 Calculation .8

5.3 Expert opinion .8

5.4 Interlaboratory testing .8

Bibliography.9

© ISO 2010 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO/TR 12134:2010(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

In exceptional circumstances, when a technical committee has collected data of a different kind from that

which is normally published as an International Standard (“state of the art”, for example), it may decide by a

simple majority vote of its participating members to publish a Technical Report. A Technical Report is entirely

informative in nature and does not have to be reviewed until the data it provides are considered to be no

longer valid or useful.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO/TR 12134 was prepared by Technical Committee ISO/TC 45, Rubber and rubber products, Subcommittee

SC 2, Testing and analysis.

iv © ISO 2010 – All rights reserved

---------------------- Page: 4 ----------------------

ISO/TR 12134:2010(E)

Introduction

[2]

It is now a requirement that laboratories accredited to ISO/IEC 17025 take into account the measurement or

calibration uncertainties associated with any work they have performed when assessing conformity of the

material or product to a given specification. As there is an increasing requirement for traceability of

measurement, more and more technical staff find themselves faced with the task of carrying out an

uncertainty evaluation on their reported measurement results.

[1]

Currently, the primary source document for guidance on measurement uncertainty is ISO/IEC Guide 98-3 , to

which the interested reader is referred for details.

[5]

Eurolab Technical Report No. 1/2007 is a very useful guide to alternative approaches to uncertainty

[3]

evaluation, whilst ISO/TS 21748 gives guidance on the use of repeatability/reproducibility data for

uncertainty estimation.

© ISO 2010 – All rights reserved v

---------------------- Page: 5 ----------------------

TECHNICAL REPORT ISO/TR 12134:2010(E)

Rubber — Estimation of uncertainty for test methods —

Non-functional parameters

1 Scope

This Technical Report provides guidance to scientists, engineers and technicians, working in the field of

rubber materials and products, to supplement ISO/IEC Guide 98-3 and to provide additional guidance in

situations where functional relationships between input quantities (such as temperature, strain rate and time)

and derived output quantities (such as tensile strength and compression set) are unknown and where no other

guidance is available.

This Technical Report provides a summary of the classical approach that is taken in the preparation of

uncertainty budgets and provides in Clause 4 a list of selected test methods and, for each, an indication of the

factors that will make a contribution to the uncertainty budget. Clause 5 discusses how “non-functional” factors

can be taken into account in the classical approach.

2 Summary of preparing an uncertainty budget

The analysis of most measurement uncertainties can be reduced to a step-by-step procedure. This procedure

comprises the following steps:

a) define the functional relationship between the input measurements and the measurand (the quantity

being measured, e.g. tensile strength);

b) compile a list of all the factors that are expected to contribute to the uncertainty in the measurand;

c) for each of the uncertainty sources, estimate the magnitude of the uncertainty;

d) from the relationship defined in step a), estimate the effect that each functional quantity has on the

measurement result, using direct mathematical techniques;

e) for the non-functional quantities, estimate their effect through other sources, such as secondary

experimentation or expert opinion;

f) combine the uncertainties in all the input quantities to obtain the uncertainty in the output quantity;

g) express the expanded uncertainty as an interval about the measurement result within which it is

anticipated, with a stated level of confidence, that the measurand will lie.

© ISO 2010 – All rights reserved PROOF/ÉPREUVE 1

---------------------- Page: 6 ----------------------

ISO/TR 12134:2010(E)

3 The elements of the uncertainty budget

Taking each of the seven steps in turn:

a) The functional relationship between the measurand and its input variables is given in the International

Standard for the test method being examined. For example, the functional relationship for tensile

strength, σ, is given by:

F

σ =

wt

where

F is the force at break;

w is the test piece width;

t the test piece thickness.

b) See Clause 4 for listings of factors that can be expected to have some influence on the result of the test.

c) Estimating the magnitude of the uncertainty, u(x), is often the most difficult part in preparing the

uncertainty budget. Two main types are identified in ISO/IEC Guide 98-3.

Type A uncertainties relate to random effects. Typically, the type A evaluation will be applied to the

material property data that has been determined by the test method, e.g. the tensile strength,

compression set or volume swell. Such data will generally be normally distributed about their mean (or

sufficiently close to a normal distribution for the deviation to be insignificant) so that an estimate of the

standard uncertainty can be deduced by means of the usual statistical procedures. The standard

uncertainty is given by the standard error of the mean.

The second, type B, relates to systematic effects and is applied to the analysis of such parameters as the

calibration of an instrument or the drift between calibrations. Such sources of uncertainty should be

evaluated on the basis of the information available, such as a calibration certificate, the manufacturer's

specifications or professional judgement and past experience. Part of that experience is in deciding what

kind of distribution the uncertainty will take. Often this is not a normal distribution, and rectangular or

sometimes triangular distributions are often encountered. Reference should be made to

ISO/IEC Guide 98-3 for further details, but in all cases the standard uncertainty is given by the standard

deviation of the distribution that has been chosen.

d) Once the standard uncertainty for each of the functional factors has been estimated, the sensitivity

coefficient for each must be found. This is the first derivative of the measurand with respect to the

parameter being considered. Thus, for tensile strength, the sensitivity coefficient, c, for the force is simply:

∂σ 1

c==

F

∂F wt

while for the width it is:

∂−σ F

c==

w

2

∂w

wt

An alternative to formal differentiation

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.