ISO 17357:2002

(Main)Ships and marine technology — High-pressure floating pneumatic rubber fenders

Ships and marine technology — High-pressure floating pneumatic rubber fenders

ISO 17357:2002 specifies the material, performance and dimensions of high-pressure floating pneumatic rubber fenders, which are intended to be used for the berthing and mooring of a ship to another ship or berthing structure. It also specifies the test and inspection procedures for high-pressure floating pneumatic rubber fenders. ISO 17357:2002 does not address any safety hazards associated with its use. It is the user's responsibility to establish appropriate safety and health practices and determine the applicability of regulatory limitations before using this standard.

Navires et technologie maritime — Éperons pneumatiques flottants à haute pression

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 17357

First edition

2002-11-15

Ships and marine technology — High-

pressure floating pneumatic rubber fenders

Navires et technologie maritime — Éperons pneumatiques flottants à haute

pression

Reference number

ISO 17357:2002(E)

© ISO 2002

---------------------- Page: 1 ----------------------

ISO 17357:2002(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but shall not be

edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In downloading this file,

parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation parameters

were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In the unlikely event

that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2002

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or ISO's

member body in the country of the requester.

ISO copyright office

Case postale 56 CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.ch

Web www.iso.ch

Printed in Switzerland

©

ii ISO 2002 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 17357:2002(E)

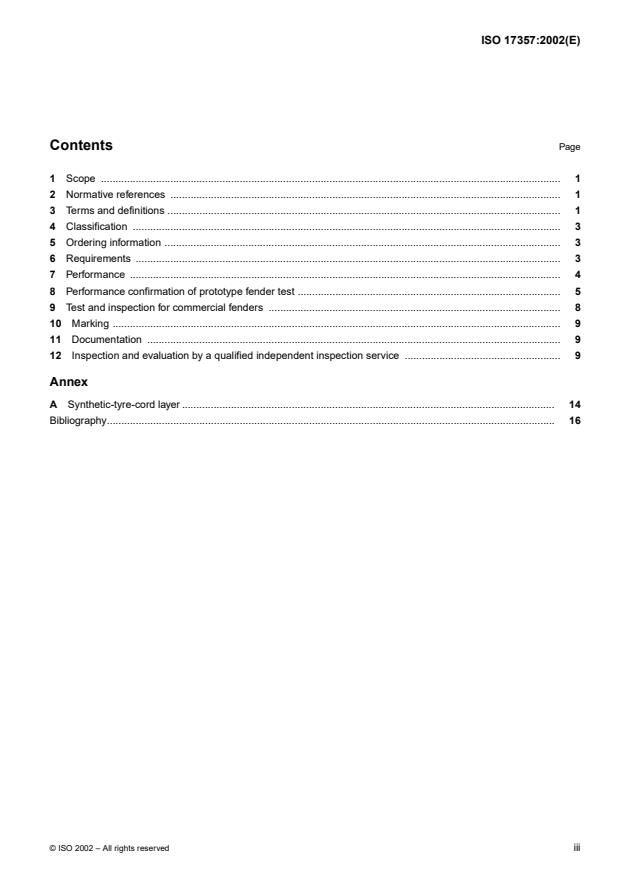

Contents Page

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Classification . 3

5 Ordering information . 3

6 Requirements . 3

7 Performance . 4

8 Performance confirmation of prototype fender test . 5

9 Test and inspection for commercial fenders . 8

10 Marking . 9

11 Documentation . 9

12 Inspection and evaluation by a qualified independent inspection service . 9

Annex

A Synthetic-tyre-cord layer . 14

Bibliography. 16

©

ISO 2002 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 17357:2002(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies (ISO

member bodies). The work of preparing International Standards is normally carried out through ISO technical

committees. Each member body interested in a subject for which a technical committee has been established has

the right to be represented on that committee. International organizations, governmental and non-governmental, in

liaison with ISO, also take part in the work. ISO collaborates closely with the International Electrotechnical

Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 3.

Draft International Standards adopted by the technical committees are circulated to the member bodies for voting.

Publication as an International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this International Standard may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights.

International Standard ISO 17357 was prepared by Technical Committee ISO/TC 8, Ships and marine technology,

Subcommittee SC 9, General requirements.

Annex A of this International Standard is for information only.

©

iv ISO 2002 – All rights reserved

---------------------- Page: 4 ----------------------

ISO 17357:2002(E)

Introduction

Throughout this International Standard, the minimum essential criteria are identified by the use of the key word

“shall”. Recommended criteria are identified by the use of the key word “should”, and while not mandatory are

considered to be of primary importance in providing serviceable, economical and practical connectors. Deviation

from the recommended criteria should occur only after careful consideration, extensive testing and thorough service

evaluation have shown alternative methods to be satisfactory.

©

ISO 2002 – All rights reserved v

---------------------- Page: 5 ----------------------

INTERNATIONAL STANDARD ISO 17357:2002(E)

Ships and marine technology — High-pressure floating pneumatic

rubber fenders

1 Scope

This International Standard specifies the material, performance and dimensions of high-pressure floating pneumatic

rubber fenders, which are intended to be used for the berthing and mooring of a ship to another ship or berthing

structure. It also specifies the test and inspection procedures for high-pressure floating pneumatic rubber fenders.

This International Standard does not address any safety hazards associated with its use. It is the user's responsibility

to establish appropriate safety and health practices and determine the applicability of regulatory limitations before

using this standard.

The documents in the Bibliography provide information on the usage of the fenders.

2 Normative references

The following normative documents contain provisions which, through reference in this text, constitute provisions of

this International Standard. For dated references, subsequent amendments to, or revisions of, any of these

publications do not apply. However, parties to agreements based on this International Standard are encouraged to

investigate the possibility of applying the most recent editions of the normative documents indicated below. For

undated references, the latest edition of the normative document referred to applies. Members of ISO and IEC

maintain registers of currently valid International Standards.

ISO 34-1:1994, Rubber, vulcanized or thermoplastic — Determination of tear strength — Part 1: Trouser, angle and

crescent test pieces

ISO 37:1994, Rubber, vulcanized or thermoplastic — Determination of tensile stress-strain properties

ISO 188:1998, Rubber, vulcanized or thermoplastic — Accelerated ageing and heat resistance tests

ISO 815:1991, Rubber, vulcanized or thermoplastic — Determination of compression set at ambient, elevated or low

temperatures

ISO 1382:1996, Rubber — Vocabulary

ISO 1431-1:1989, Rubber, vulcanized or thermoplastic — Resistance to ozone cracking — Part 1: Static strain test

ISO 7619:1997, Rubber — Determination of indentation hardness by means of pocket hardness meters

ISO 12236:1996, Geotextiles and geotextile-related products — Static puncture test (CBR test)

3 Terms and definitions

For the purposes of this International Standard, the definitions given in ISO 1382 shall apply, together with the

following.

©

ISO 2002 – All rights reserved 1

---------------------- Page: 6 ----------------------

ISO 17357:2002(E)

3.1

floating pneumatic rubber fender

fender which is made of synthetic-cord-reinforced rubber sheet with compressed air inside to enable it to float on the

water and work as a shock absorber between two ships, or between ships and berthing structures when they come

alongside each other on the water

NOTE The fenders have sometimes been colloquially referred to as “Yokohama fenders” or “Yokohama type fenders”. These are

examples of suitable products available commercially. This information is given for the convenience of users of this International

Standard and does not constitute an endorsement by ISO of these products.

3.2

outer rubber

rubber layer that covers the outside of the fender to protect the cord layers and the inner liner rubber from abrasion

and other external forces

3.3

inner rubber

liner of a rubber membrane that seals the pressurized air inside the fender

3.4

synthetic-tyre-cord layer for reinforcement

layer made of synthetic-tyre-cord fabric, which maintains the internal air pressure of the fender

NOTE As the main fibres of the synthetic-tyre-cord fabric are not braided like synthetic canvas fabric or synthetic belt fabric, there

are advantages for its fatigue-resistance performance and pressure-holding performance. See annex A.

3.5

bead ring

steel ring which is placed at one end (or both ends) of the fender and holds the end of cord layers

3.6

flange opening

steel flange, which is mounted on the fender, to which an air valve or safety valve can be adapted

3.7

guaranteed energy absorption

energy that the fender can absorb without permanent deformation or failure

3.8

reaction force

force produced by a fender reacting to a compressive force

NOTE The reactive force is equal to the force of the air pressure of the fender multiplied by the area of the fender in contact with

the ship or berthing structure.

3.9

initial internal pressure

air pressure at which an uncompressed fender operates

3.10

endurable pressure

inner pressure at which a fender bursts

3.11

net-type fender

fender which is covered by a protection net consisting of either chain, wire or fibre and usually with tyres or rubber

sleeves

©

2 ISO 2002 – All rights reserved

---------------------- Page: 7 ----------------------

ISO 17357:2002(E)

3.12

sling-type fender

fender which is designed to be used without a protection net

4 Classification

4.1 Fender types

Fender types are defined as follows:

a) Type I — net type;

b) Type II — sling type.

4.2 Initial internal pressure

Initial internal pressures are defined as follows:

a) pneumatic 50 (initial internal pressure 50 kPa);

b) pneumatic 80 (initial internal pressure 80 kPa).

5 Ordering information

The fender purchase order, contract or inquiry should state the following.

— The ISO standard number and applicable year, i.e. ISO 17357:2002.

If the purchasers request other sizes, they shall satisfy the requirements of the second paragraph of 6.3.2.

— Fender size: nominal fender diameter and length: see Table 1 or Table 2.

— Fender type: see 4.1.

— Initial internal pressure: see 4.2.

— Fender colour. If not specified, the colour shall be black.

— If a safety valve is required for fenders smaller than 2 500 mm in diameter, see 6.1.7.

— If an identification system is required, see clause 10.

— If inspection/evaluation by a major classification society is required, see clause 12.

6 Requirements

6.1 General fender requirements

6.1.1 Floating pneumatic rubber fenders shall consist of a cylindrical air bag with hemispherical heads at both ends,

which shall be filled with compressed air. The basic body construction of this fender shall consist of an outer rubber,

synthetic-tyre-cord layers, see annex A, for reinforcement and an inner rubber. All of these shall be vulcanized firmly.

NOTE Alternative reinforcement methods for synthetic-tyre-cord layers may be considered if their strength and durability are

designed and proven to be equal to, or superior to, the synthetic-tyre-cord layers after exhaustive trials.

6.1.2 The outer rubber shall protect the cord layers and inner rubber from abrasion and other external forces. This

rubber compound shall have sufficient tensile and tear resistance strength to withstand anticipated weather

conditions and severe usage. This rubber shall satisfy the values specified in Table 3.

6.1.3 The inner rubber layer shall seal the air inside. This rubber shall satisfy the requirements specified in Table 3.

©

ISO 2002 – All rights reserved 3

---------------------- Page: 8 ----------------------

ISO 17357:2002(E)

6.1.4 The reinforcement synthetic-tyre-cord layers shall be strong enough to hold the internal pressure. In both

compressed and non-compressed situations, the fender's endurable pressure shall be as in Table 4 or Table 5.

6.1.5 The flange opening shall be at either end, or both ends, for convenience of air charge and water filling, if

required.

6.1.6 The end of the reinforcement-cord layers shall enter the bead ring and be turned up outside the bead ring,

which is built-in at the flange opening. For Type I (net type) fenders, the bead ring and turning up on construction may

be excluded.

6.1.7 Fenders of diameter 2 500 mm and larger shall be equipped with a safety valve for releasing excess internal

pressure when the fenders are over-compressed accidentally. Fenders which are smaller than 2 500 mm in diameter,

can be equipped with a safety valve if required.

6.1.8 The fender shall be equipped with an air valve for inflation and checking air pressure.

6.2 Type requirements

6.2.1 Type I (net type) fenders shall be covered by a chain net, wire net or fibre net. Each end of longitudinal chains,

wires or fibres shall be linked together with one or two ring(s), which shall be connected with a guy-chain or guy-rope.

Usually, these nets will be fitted with used tyres or rubber sleeves to provide additional protection to the fender body.

6.2.2 Type II (sling type) fenders shall have a lifting device on each end, which shall be connected with a guy-chain

or guy-rope.

6.3 Pressure requirements

6.3.1 Pneumatic 50: the internal pressure, endurable pressure, safety-valve setting pressure and hydraulic test

pressure shall be as specified in Table 4.

6.3.2 Pneumatic 80: the internal pressure, endurable pressure, safety-valve setting pressure and hydraulic test

pressure shall be as specified in Table 5.

Sizes not listed in Tables 4 and 5 shall satisfy all the requirements in this subclause, using the pressure requirements

of the next-larger-diameter size. (Example: a 2 200 mm diameter fender shall satisfy the pressure requirements of a

2 500 mm diameter fender.)

7 Performance

7.1 Specification of performance

The performance of floating pneumatic rubber fenders shall be specified in terms of guaranteed energy absorption

(GEA), reaction force at GEA deflection, and hull pressure at GEA deflection.

7.2 Performance curves

The relationship between the deflection percentage, reaction force, inner pressure (which is equal to the hull

pressure) and energy absorption is shown in Figure 1. The reaction force, the inner pressure and the energy

absorption of the fender increase as the deflection percentage increases. From the GEA value, point A is determined

on the energy absorption curve and the corresponding deflection percentage is read as the GEA deflection. The

reaction force and the hull pressure are then obtained at that deflection percentage value.

7.3 Fender performance

7.3.1 Pneumatic 50: the fenders shall comply with the values specified in Table 1.

©

4 ISO 2002 – All rights reserved

---------------------- Page: 9 ----------------------

ISO 17357:2002(E)

7.3.2 Pneumatic 80: The fenders shall comply with the values specified in Table 2.

60±5%

7.3.3 Guaranteed energy absorption (GEA) values shown in Table 1 or Table 2 shall be obtained at

deflection.

7.3.4 The tolerance of reaction force at the GEA deflection shall be ± 10 %.

7.3.5 Fender performance can be calculated by the formula, which shall be established using the performance test

described in 8.1.

8 Performance confirmation of prototype fender test

8.1 General

Each fender, involving different methods of basic construction and/or design, shall require a prototype test.

Fenders of lesser diameter than a prototype confirmed fender, incorporating the same basic design, construction and

fabrication methods but having fewer plies due to the smaller diameter, but satisfying all requirements of this

International Standard, do not require a prototype test.

8.2 Performance test, parallel compression test

8.2.1 To determine the performance of the fenders given in clause 7, a performance test shall be performed.

Applying a compressive force perpendicularly to the fender, the fender shall be compressed until its energy

absorption reaches the guaranteed energy absorption (GEA) value. The compression speed shall not exceed

80 mm/min. The reaction force and internal pressure shall be recorded at least every 5% percentage deflection. The

percent

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.