ISO/TS 15338:2009

(Main)Surface chemical analysis — Glow discharge mass spectrometry (GD-MS) — Introduction to use

Surface chemical analysis — Glow discharge mass spectrometry (GD-MS) — Introduction to use

ISO/TS 15338:2009 gives guidelines for the operation of glow discharge mass spectrometry (GD‑MS) instruments and recommendations for the use of GD‑MS. It is intended to be read in conjunction with the instrument manufacturers' manuals and recommendations.

Analyse chimique des surfaces — Spectrométrie de masse à décharge luminescente (GD-MS) — Introduction à l'utilisation

General Information

Relations

Standards Content (Sample)

TECHNICAL ISO/TS

SPECIFICATION 15338

First edition

2009-04-01

Surface chemical analysis — Glow

discharge mass spectrometry (GD-MS) —

Introduction to use

Analyse chimique des surfaces — Spectrométrie de masse à décharge

luminescente (GD-MS) — Introduction à l'utilisation

Reference number

ISO/TS 15338:2009(E)

©

ISO 2009

---------------------- Page: 1 ----------------------

ISO/TS 15338:2009(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

COPYRIGHT PROTECTED DOCUMENT

© ISO 2009

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2009 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/TS 15338:2009(E)

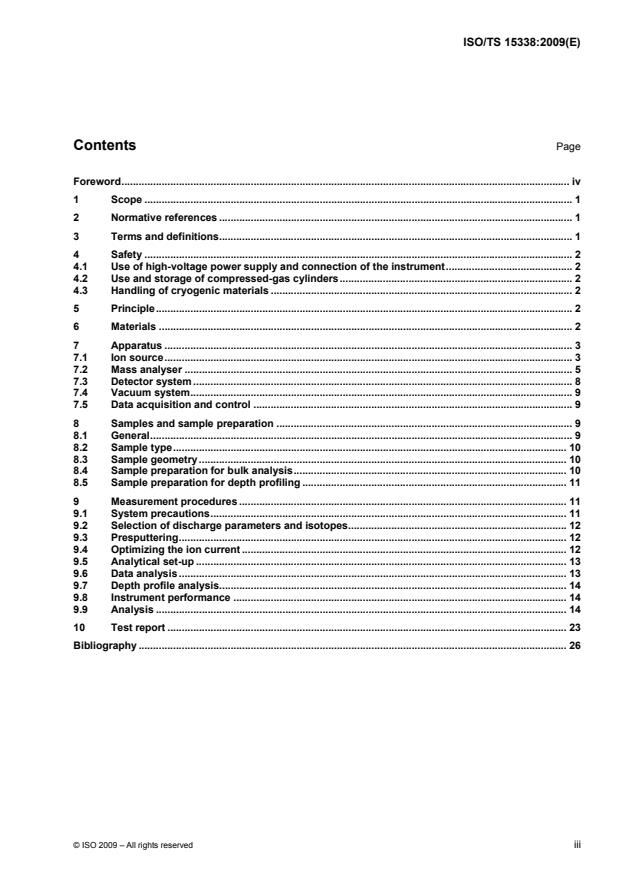

Contents Page

Foreword. iv

1 Scope . 1

2 Normative references . 1

3 Terms and definitions. 1

4 Safety . 2

4.1 Use of high-voltage power supply and connection of the instrument. 2

4.2 Use and storage of compressed-gas cylinders. 2

4.3 Handling of cryogenic materials . 2

5 Principle. 2

6 Materials . 2

7 Apparatus . 3

7.1 Ion source. 3

7.2 Mass analyser . 5

7.3 Detector system . 8

7.4 Vacuum system. 9

7.5 Data acquisition and control . 9

8 Samples and sample preparation . 9

8.1 General. 9

8.2 Sample type. 10

8.3 Sample geometry. 10

8.4 Sample preparation for bulk analysis. 10

8.5 Sample preparation for depth profiling . 11

9 Measurement procedures . 11

9.1 System precautions. 11

9.2 Selection of discharge parameters and isotopes. 12

9.3 Presputtering. 12

9.4 Optimizing the ion current . 12

9.5 Analytical set-up . 13

9.6 Data analysis . 13

9.7 Depth profile analysis. 14

9.8 Instrument performance . 14

9.9 Analysis . 14

10 Test report . 23

Bibliography . 26

© ISO 2009 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO/TS 15338:2009(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

In other circumstances, particularly when there is an urgent market requirement for such documents, a

technical committee may decide to publish other types of document:

— an ISO Publicly Available Specification (ISO/PAS) represents an agreement between technical experts in

an ISO working group and is accepted for publication if it is approved by more than 50 % of the members

of the parent committee casting a vote;

— an ISO Technical Specification (ISO/TS) represents an agreement between the members of a technical

committee and is accepted for publication if it is approved by 2/3 of the members of the committee casting

a vote.

An ISO/PAS or ISO/TS is reviewed after three years in order to decide whether it will be confirmed for a

further three years, revised to become an International Standard, or withdrawn. If the ISO/PAS or ISO/TS is

confirmed, it is reviewed again after a further three years, at which time it must either be transformed into an

International Standard or be withdrawn.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO/TS 15338 was prepared by Technical Committee ISO/TC 201, Surface chemical analysis, Subcommittee

SC 8, Glow discharge spectrometry, based on Australian Standard AS 3685:1998.

iv © ISO 2009 – All rights reserved

---------------------- Page: 4 ----------------------

TECHNICAL SPECIFICATION ISO/TS 15338:2009(E)

Surface chemical analysis — Glow discharge mass

spectrometry (GD-MS) — Introduction to use

1 Scope

This Technical Specification gives guidelines for the operation of glow discharge mass spectrometry (GD-MS)

instruments and recommendations for the use of GD-MS. It is intended to be read in conjunction with the

instrument manufacturers’ manuals and recommendations.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 18115, Surface chemical analysis — Vocabulary

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 18115 and the following apply.

3.1

accuracy of measurement

closeness of the agreement between a result and the accepted reference value

3.2

elemental intensity

amount of ion current recorded for a particular element

3.3

pin cell

sample cell used for the analysis of wire and rod samples

3.4

precision of measurements

closeness of the agreement between independent test results obtained under stipulated conditions, normally

reported as a standard deviation

3.5

pin, rod and wire samples

samples with cylindrical or square cross-section of nominal length typically 20 mm and not normally exceeding

10 mm across

3.6

transmission

ratio of the number of ions reaching the detector relative to the number of ions entering the mass analyser

© ISO 2009 – All rights reserved 1

---------------------- Page: 5 ----------------------

ISO/TS 15338:2009(E)

4 Safety

4.1 Use of high-voltage power supply and connection of the instrument

Electrical connection should comply with the regulations in force. Particular care should be taken to ensure

that connection of the instrument to ground is correct, and the efficiency of the ground connection should be

checked.

4.2 Use and storage of compressed-gas cylinders

The compressed-gas cylinders should be regularly tested by the appropriate authorities. Cylinders should not

be stored or used inside the laboratory. Rather, they should be located outside the laboratory in a place that is

well ventilated, away from direct heat, and accessible to service and safety personnel. The cylinders should

be provided with suitable pressure-reducing valves. If more than one cylinder is to be used or stored in close

proximity, it is advisable to indicate in some way which cylinder or cylinders are currently in use.

4.3 Handling of cryogenic materials

Vessels containing cryogenic materials should be located so as to minimize the risk to personnel. Areas

where cryogenic liquids are stored and used should be ventilated to prevent the accumulation of gas or

vapour which could evaporate from the liquid. It is good practice to keep areas where cryogenic liquids are

used very clean. All transfer operations should be in accordance with statutory requirements. When a

cryogenic liquid is being transferred from one vessel to another, precautions should be taken to minimize any

spills and splashing. The requirements of the relevant regulatory authorities should also be met.

5 Principle

In a glow discharge source, electrical power is supplied between the sample (cathode) and the anode by a

power supply typically operated in direct current (dc) at 0,5 kV to 2 kV and 1 mA to 300 mA. Argon (or another

inert gas such as neon, krypton or helium) is introduced into the discharge cell. The pressure inside the

discharge cell is typically a few hundred pascals (Pa). A potential difference is applied between the cathode

and the anode and a glow discharge (plasma) is established. Sample material (single atoms and/or clusters)

which is sputtered by ions and neutrals diffuses into the plasma.

Ions formed in the glow discharge are extracted from the ion source and pass into a mass analyser. The mass

analyser is used to transmit ions of given mass-to-charge ratio to the detector(s). The ions reaching the

detector(s) are measured as ion current or counted by a counting system. This information is stored in a

computer system. Elemental mass fractions are typically calculated by the instrument software using the ion

currents of isotopes, by normalizing the signal to the signal of a matrix element and subsequently comparing

the normalized signals with those arising from the corresponding elements in calibration samples.

6 Materials

6.1 Deionized water, 18 MΩ⋅cm or better.

6.2 Argon gas, or other plasma support gases, of purity better than 99,999 9 % or in accordance with the

recommendations of the instrument manufacturer.

6.3 Liquid nitrogen, for cryogenic cooling of the discharge cell.

6.4 Compressed gas, to operate pneumatic valves.

2 © ISO 2009 – All rights reserved

---------------------- Page: 6 ----------------------

ISO/TS 15338:2009(E)

7 Apparatus

7.1 Ion source

7.1.1 General

A glow discharge ion source consists of a glow discharge cell and a power supply. In some designs, the ion

source will also contain a series of focusing plates, external to the cell, whose function is to extract ions from

the cell and focus these ions into the mass spectrometer.

Typically the body of the discharge cell is connected to the anode output of the power supply. The sample

serves in the glow discharge cell as a cathode and is connected to the cathode output of the power supply.

Discharge cells have been designed to accommodate samples in the geometries recommended in 8.3, and

examples of discharge cells are illustrated with the appropriate sample holders in Figures 1 and 2.

Key

1 sample holder

2 sample

3 insulator

4 ion exit slit

5 anode plate

6 cathode plate

Figure 1 — Example of a cell used for the analysis of pin samples

© ISO 2009 – All rights reserved 3

---------------------- Page: 7 ----------------------

ISO/TS 15338:2009(E)

Key

1 sample cathode

2 spring

3 insulator

4 cell body

5 ion exit slit

6 anode plate

Figure 2 — Example of a cell used for the analysis of flat samples

7.1.2 Source parameters

The source parameters are as follows:

a) Electrical

⎯ potential difference between anode and cathode;

⎯ current;

⎯ power.

b) Geometrical

⎯ dimension of sample exposed to plasma;

⎯ anode-to-sample distance;

⎯ cathode dimension;

⎯ mask dimension, where appropriate.

4 © ISO 2009 – All rights reserved

---------------------- Page: 8 ----------------------

ISO/TS 15338:2009(E)

c) Gas type and pressure.

d) Cell temperature.

e) Type of sample.

7.1.3 Operational modes

The direct-current source may be operated in different modes, including:

a) constant current with potential difference adjusted by adjusting the plasma gas pressure;

b) constant potential difference with current adjusted by adjusting the plasma gas pressure;

c) constant current with plasma gas pressure adjusted by adjusting the potential difference.

The discharge pressure may be regulated using a mass flow controller, needle valve or knife edge valve. For

some types of GD-MS instrument, the high accelerating voltages encountered require a capillary in the gas

line to prevent electrical breakdown through the gas line. Radio-frequency-powered GD sources are also

being developed for GD-MS.

7.2 Mass analyser

There are two types of mass analyser commonly used for glow discharge mass spectrometry: double-

focussing magnetic-sector instruments and quadrupole instruments. Other types, like time-of-flight instruments,

are also becoming more common.

a) Sector mass spectrometer: This type of instrument (see Figure 3) typically utilizes an electromagnet

and an electrostatic analyser (ESA). The magnet achieves mass separation and, as the magnetic field is

increased, ions with greater mass-to-charge ratio are transmitted. The ESA acts as an energy filter and

transmits only those ions with the appropriate energies.

This arrangement permits high-transmission and high-resolution operation, giving accurate mass

information advantageous with complex sample matrices where there is an increased possibility of

interferences. A resolving power of 4 000 is sufficient to overcome most common interferences.

© ISO 2009 – All rights reserved 5

---------------------- Page: 9 ----------------------

ISO/TS 15338:2009(E)

Key

1 ion beam

2 source slit

3 magnet

4 intermediate slit

5 ESA

6 detector slit

7 detector

Figure 3 — Schematic diagram of a magnetic-sector mass analyser

b) Quadrupole: This type of mass spectrometer consists of four parallel rods whose centres form the

corners of a square and whose diagonally opposite poles are connected (see Figure 4). The voltage

applied to the rods is a superposition of a static potential and a sinusoidal radio-frequency potential. The

motion of an ion in the x and y directions is described by the Mathieu equation, the solutions of which

show that ions in a particular m/z (mass-to-charge ratio) range can be transmitted along the quadrupole

axis.

Whilst a quadrupole instrument does not have the high resolution of a magnetic-sector instrument (the

resolving power at mass-to-charge ratio 100 is usually less than 200), it has a much faster scanning

speed, is compact and is able to achieve low detection limits if interferences are kept low.

6 © ISO 2009 – All rights reserved

---------------------- Page: 10 ----------------------

ISO/TS 15338:2009(E)

Key

1 from ion source

2 non-resonant ion

3 resonant ion

4 detector

5 d.c.

6 a.c.

Figure 4 — Schematic diagram of a quadrupole mass analyser

c) TOF (time-of-flight) mass spectrometer: In this type of mass spectrometer, an ensemble of ions is

accelerated by an electric field and then allowed to drift a certain distance before impinging on an ion

detector (see Figure 5). In the accelerating field, all ions receive the same kinetic energy, which can be

2

equated to ½mv . Therefore, ions with a lower m/z (mass-to-charge ratio) will have a higher velocity and

will arrive at the detector earlier than ions with a higher m/z. By measuring the arrival time of ions, the m/z

of those ions can be determined.

Whilst quadrupole instruments and sector instruments are m/z filters, TOF instruments do not have to

scan in order to record a mass spectrum and therefore have the potential for a higher-duty cycle. TOF

instruments intrinsically have a large mass range and good mass accuracy. They also have reasonably

good resolving power, allowing them to overcome some interferences.

© ISO 2009 – All rights reserved 7

---------------------- Page: 11 ----------------------

ISO/TS 15338:2009(E)

Key

1 ion source 5 high-voltage pulser (starts the ions)

2 high-mass particle 6 detector (generates stop signal)

3 low-mass particle 7 signal

4 extractor 8 data-acquisition system (records time of flight)

a

Drift.

b

One start signal.

c

Multiple stop signals.

Figure 5 — Schematic diagram of a time-of-flight mass analyser

NOTE Other types of mass spectrometer (e.g. ion trap mass spectrometers) are being adapted for use with glow

discharge ion sources.

7.3 Detector system

As a consequence of the wide mass fraction range measured using GD-MS, usually two detectors are

required and/or needed, as follows:

a) Ion signals from matrix and major trace elements present at mass fractions typically above 0,1 % are

measured using a coarse detector such as a Faraday plate or an electron multiplier, operating in the

analogue mode. These detectors simply measure the current generated by the ion beam striking the

detector.

b) Ion signals from trace elements present at mass fractions typically below 0,1 % are measured using ion-

1)

counting techniques. Examples of ion-counting detectors are the Daly detector and the Channeltron ,

multi-channel plate and venetian-blind electron multipliers.

NOTE Any differences in the response of the detectors are reflected in the instrument calibration.

®

1) Channeltron is the trade name of a product supplied by Burle. This information is given for the convenience of users

of this Technical Specification and does not constitute an endorsement by ISO of this product.

8 © ISO 2009 – All rights reserved

---------------------- Page: 12 ----------------------

ISO/TS 15338:2009(E)

7.4 Vacuum system

A glow discharge ion source operates at a pressure of approximately 100 Pa, but optimum mass spectrometer

performance, in terms of transmission, resolution and abundance sensitivity, requires a pressure in the mass

−4

analyser of less than 1 × 10 Pa. To achieve such a vacuum level, differential pumping is required. This

means that both the ion source housing and the mass analyser are pumped independently.

There are diverse designs:

a) Diode geometry type source

−2

The resulting pressure outside the cell in the ion source is typically 1 × 10 Pa under normal operating

conditions. In addition, the test sample is usually introduced via a sample interlock, which is evacuated to

typically 1 Pa using a rotary pump or other suitable primary vacuum pump. This maintains the integrity of the

vacuum inside the source housing and minimizes contamination by atmospheric gases.

Alternatively, the source can be isolated from the mass analyser via an interlock and/or another device to

protect the mass analyser while the test sample is being changed.

b) Grimm type source

The resulting pressure outside the cell is usually in the same range as that inside the cell, which is typically

around 100 Pa under normal operating conditions. The test sample is introduced at atmospheric pressure and,

after closing the cover around the sample holder, the entire region is pumped to typically 1 Pa using a scroll

pump or another suitable primary vacuum pump. During the sample exchange there is a continuous flow of

discharge gas through the cell and cover to prevent atmospheric gases from entering the source.

The source is isolated from the mass analyser via a slide valve to maintain the vacuum of the mass analyser

while the test sample is being changed.

7.5 Data acquisition and control

The data-acquisition system should be capable of the following:

a) selection of analytes to be determined and isotopes to be monitored;

b) monitoring of key instrument parameters (see 9.8);

c) data acquisition, analysis and storage;

d) data processing;

e) report generation;

f) archiving of data.

8 Samples and sample preparation

8.1 General

The following guidelines should be followed for general sample preparation:

a) use inert materials, e.g. polytetrafluorethylene (PTFE) or polypropylene beakers, when etching samples;

b) use non-contaminating materials for all equipment in contact with the sample;

c) use high-purity acids and solvents.

© ISO 2009 – All rights reserved 9

---------------------- Page: 13 ----------------------

ISO/TS 15338:2009(E)

8.2 Sample type

Glow discharge mass spectrometry is suitable for the trace and ultra-trace elemental analysis of metals, alloys,

semiconductors and non-conductors and for depth-profiling applications.

Samples should preferably be in the form of solid material, for example wires, rods, pins, sheets, coupons,

irregular pieces, chunks, flat wafers, targets or powders.

NOTE There are also potential applications for GD-MS in the analysis of liquid residues and organic samples.

8.3 Sample geometry

Various instrument manufacturers have developed sample holders for specific sample geometries,

e.g. pin/rod/wire samples typically 20 mm in length and up to 10 mm across. For flat samples, the sputtered

area is usually 4 mm to 10 mm in diameter. The maximum size of the sample is restricted by the size of the

sample holder. Smaller sample sizes are achievable, but not normally recommended because of the resulting

reduction in the signal. The thickness of flat samples is not critical and is restricted only by the sample holder

design.

8.4 Sample preparation for bulk analysis

8.4.1 General

The objective of sample preparation is to provide a clean representative test sample of the sample under

investigation.

All test samples should be of the same nominal size as the calibration or reference sample.

For flat samples, a gas-tight surface is required to seal against the sample holder to maintain the proper argon

pressure inside the discharge cell.

8.4.2 Metals, alloys and semiconductors

Samples may be formed into the required geometry by many methods, e.g. casting, rolling, drawing, cutting,

machining or etching.

Surface finishing may involve machining, polishing, etching, solvent cleaning or drying.

8.4.3 Powders

Powders may be either conducting or non-conducting and should be treated as follows:

a) Conducting powders should be compacted using a die compaction press into an appropriate geometry in

accordance with 8.3.

b) Non-conducting powders are commonly mixed with a conducting medium. This mixture should then be

treated as a conducting powder.

The conducting medium should provide a stable discharge whilst providing sufficient signal to perform a

meaningful analysis. In addition, a medium should be chosen that minimizes interferences with the analyte(s)

to be determined.

10 © ISO 2009 – All rights reserved

---------------------- Page: 14 ----------------------

ISO/TS 15338:2009(E)

8.4.4 Non-conducting samples

For analysis with a direct current source, a secondary cathode (a metal mask containing an aperture) is

placed on the surface of the non-conducting sample such that the mask is maintained at the cathode potential.

The secondary cathode should provide a stable discharge whilst providing a sufficient signal to perform a

meaningful analysis. In addition, the material of which the secondary cathode is made should be chosen to

minimize interferences with the analyte(s) to be determined.

8.5 Sample preparation for depth profiling

Surface preparation may not be necessary or desired. If preparation is carried out, care should be taken not to

contaminate the surface or remove surface material of interest.

9 Measurement procedures

9.1 System precautions

9.1.1 General

For general operation of the system, refer to the manufacturers’ manuals and recommendations.

The following general precautions should be observed while operating the system:

a) It is good practice to wear a pair of powder-free gloves when handling vacuum components, including all

parts of the discharge cell and extraction optics. Vacuum components should be kept in a dust- and

moisture-free environment, such as a desiccator cabinet.

b) No specific personal protection equipment is required during normal operation. However, the operator

should be aware of any potential hazards associated with specific samples. For example, there is a

possibility of toxic materials accumulating in traps, pumps and other reservoirs within the instrument.

9.1.2 Interferences

Interference may occur when two ions (possibly molecular fragments or species) have the same or a similar

mass-to-charge ratio. The significance of this interference will vary depending upon the type of mass

spectrometer. Where these interferences occur, they cannot be generally resolved using a quadrupole

instrument, but in most cases they can be resolved using a magnetic-sector instrument. The most appropriate

isotopes, free of interferences and with the highest abundances possible, should be chosen. This will vary

between matrices.

As a general guide, for a metal, M, in a discharge atmosphere of argon, Ar, ionization processes produce a

+ + +

stable spectrum consisting mainly of singly charged atomic ions, M and Ar , with some dimer ions, M and

2

+ 2+ 3+ 2+

Ar , present. Multiply charged argon ions, Ar and Ar , and the like are evident. M ions are more

2

significant for metals with a low second-ionization potential. Combinations of metal and argon species, such

+ +

as MAr and MAr , are seen but, in general, the more complex the species,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.