ISO 10810:2019

(Main)Surface chemical analysis — X-ray photoelectron spectroscopy — Guidelines for analysis

Surface chemical analysis — X-ray photoelectron spectroscopy — Guidelines for analysis

This document is intended to aid the operators of X-ray photoelectron spectrometers in their analysis of typical samples. It takes the operator through the analysis from the handling of the sample and the calibration and setting-up of the spectrometer to the acquisition of wide and narrow scans and also gives advice on quantification and on preparation of the final report.

Analyse chimique des surfaces — Spectroscopie de photoélectrons par rayons X — Lignes directrices pour l'analyse

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 10810

Second edition

2019-08

Surface chemical analysis — X-ray

photoelectron spectroscopy —

Guidelines for analysis

Analyse chimique des surfaces — Spectroscopie de photoélectrons par

rayons X — Lignes directrices pour l'analyse

Reference number

ISO 10810:2019(E)

©

ISO 2019

---------------------- Page: 1 ----------------------

ISO 10810:2019(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2019

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2019 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 10810:2019(E)

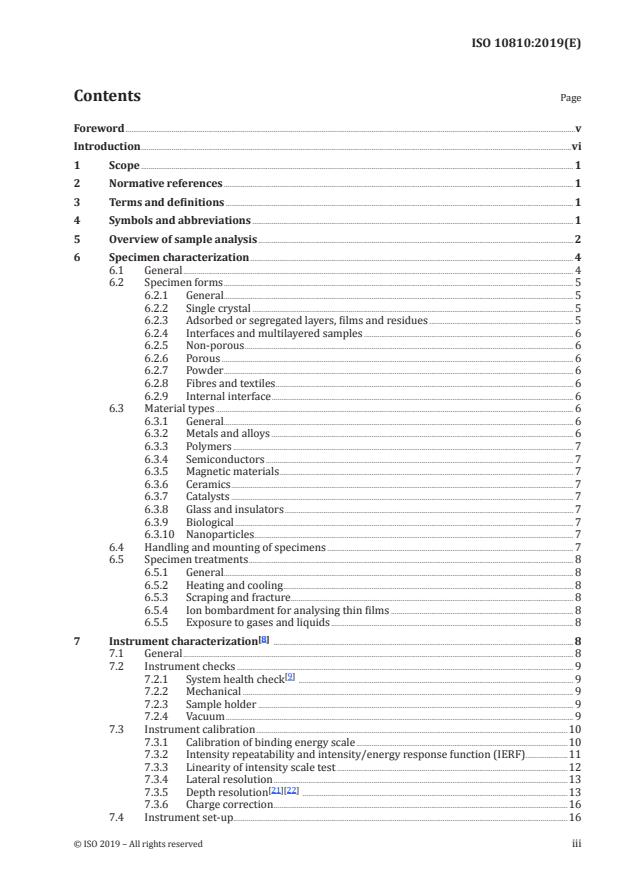

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Symbols and abbreviations . 1

5 Overview of sample analysis . 2

6 Specimen characterization . 4

6.1 General . 4

6.2 Specimen forms . 5

6.2.1 General. 5

6.2.2 Single crystal . 5

6.2.3 Adsorbed or segregated layers, films and residues . 5

6.2.4 Interfaces and multilayered samples . 6

6.2.5 Non-porous . 6

6.2.6 Porous . 6

6.2.7 Powder . . 6

6.2.8 Fibres and textiles . 6

6.2.9 Internal interface . 6

6.3 Material types . 6

6.3.1 General. 6

6.3.2 Metals and alloys . 6

6.3.3 Polymers . 7

6.3.4 Semiconductors . 7

6.3.5 Magnetic materials . 7

6.3.6 Ceramics . 7

6.3.7 Catalysts . 7

6.3.8 Glass and insulators . 7

6.3.9 Biological . 7

6.3.10 Nanoparticles . 7

6.4 Handling and mounting of specimens . 7

6.5 Specimen treatments . 8

6.5.1 General. 8

6.5.2 Heating and cooling . 8

6.5.3 Scraping and fracture . . 8

6.5.4 Ion bombardment for analysing thin films . 8

6.5.5 Exposure to gases and liquids . 8

[8]

7 Instrument characterization . 8

7.1 General . 8

7.2 Instrument checks . 9

[9]

7.2.1 System health check . 9

7.2.2 Mechanical . 9

7.2.3 Sample holder . 9

7.2.4 Vacuum . 9

7.3 Instrument calibration .10

7.3.1 Calibration of binding energy scale .10

7.3.2 Intensity repeatability and intensity/energy response function (IERF).11

7.3.3 Linearity of intensity scale test .12

7.3.4 Lateral resolution .13

[21][22]

7.3.5 Depth resolution .13

7.3.6 Charge correction .16

7.4 Instrument set-up.16

© ISO 2019 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 10810:2019(E)

7.4.1 Optimum settings .16

7.4.2 System configuration .17

8 The wide-scan spectrum .17

8.1 Data acquisition .17

8.1.1 General.17

8.1.2 Sample loading .18

8.1.3 Energy resolution .18

8.1.4 Energy range, step size and acquisition mode .18

8.1.5 X-ray source and conditions .18

8.1.6 Charge correction .19

8.1.7 Spectrum acquisition .19

8.1.8 X-ray degradation .19

8.1.9 Thin surface layer .19

8.2 Data analysis .19

8.2.1 Calibration of the binding energy scale .19

8.2.2 Peak table .20

8.2.3 Quantification .20

8.2.4 Assessment of the composition employing the Tougaard extrinsic

[42]

background .21

8.2.5 Requirement for narrow scans .21

9 The narrow scan .21

9.1 General .21

9.2 Data acquisition .21

9.2.1 Instrument settings .21

9.2.2 Choice of region .21

9.3 Data analysis .22

9.3.1 Element identification .22

9.3.2 Chemical-state identification .22

9.3.3 Quantification .23

10 Test report .26

Bibliography .28

iv © ISO 2019 – All rights reserved

---------------------- Page: 4 ----------------------

ISO 10810:2019(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see www .iso

.org/iso/foreword .html.

This document was prepared by Technical Committee ISO/TC 201, Surface chemical analysis,

Subcommittee SC 7, Electron spectroscopies.

This second edition cancels and replaces the first edition (ISO 10810:2010), which has been technically

revised. The main changes to the previous edition are as follows:

— Table 3: semiconductor wafer added as a specimen form;

— 6.2.7: paragraph replaced to reflect modern practice;

— 6.3.10: nanoparticles added as a material type;

— Clause 8 and the flow chart in Figure 6 have been thoroughly revised to improve clarity. The cells in

the flow chart now contain references to the appropriate subclause within Clause 8;

— 8.2.1: it is now pointed out that the use of the C 1s peak provides only an approximate binding

energy reference;

— 9.3.3.3: mention has been made of the use of ionised clusters of inert gas atoms for depth profiling.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/members .html.

© ISO 2019 – All rights reserved v

---------------------- Page: 5 ----------------------

ISO 10810:2019(E)

Introduction

X-ray photoelectron spectroscopy (XPS) is used extensively for the surface (1 nm to 10 nm) analysis

of materials. Elements in the sample (with the exception of hydrogen and helium) are identified from

comparisons of the measured binding energies of their core levels with tabulations of those energies

for the different elements. Their chemical states may be determined from shifts in peak positions and

other parameters compared with the data for that element in its pure elemental state. Information on

the quantities of such elements can be derived from the measured intensities of photoelectron peaks.

Calculation of the quantities of the constituent chemical species present in the surface layer studied

(outer 1 nm to 10 nm) may then be made using formulae and relative-sensitivity factors provided by the

spectrometer manufacturer or locally measured relative-sensitivity factors and appropriate software.

This guidance document is intended to aid the operators of X-ray photoelectron spectrometers in their

analysis of the surfaces (outer 1 nm to 10 nm) of typical samples.

vi © ISO 2019 – All rights reserved

---------------------- Page: 6 ----------------------

INTERNATIONAL STANDARD ISO 10810:2019(E)

Surface chemical analysis — X-ray photoelectron

spectroscopy — Guidelines for analysis

1 Scope

This document is intended to aid the operators of X-ray photoelectron spectrometers in their analysis

of typical samples. It takes the operator through the analysis from the handling of the sample and the

calibration and setting-up of the spectrometer to the acquisition of wide and narrow scans and also

gives advice on quantification and on preparation of the final report.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 18115-1, Surface chemical analysis — Vocabulary — Part 1: General terms and terms used in

spectroscopy

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 18115-1 apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https: //www .iso .org/obp

— IEC Electropedia: available at http: //www .electropedia .org/

4 Symbols and abbreviations

AES Auger electron spectroscopy

ARXPS angle-resolved X-ray photoelectron spectroscopy

CCQM consultative committee for amount of substance

CRM certified reference material

EAL effective attenuation length

FAT fixed analyser transmission

FRR fixed retard ratio

FWHM full width at half maximum

IERF intensity/energy response function

NIST National Institute of Standards and Technology

NPL National Physical Laboratory

© ISO 2019 – All rights reserved 1

---------------------- Page: 7 ----------------------

ISO 10810:2019(E)

RM reference material

S/N signal-to-noise ratio

XPS X-ray photoelectron spectroscopy

Δ difference between the measured and reference energies for Au 4f

Au 7/2

Δ difference between the measured and reference energies for Cu 2p

Cu 3/2

5 Overview of sample analysis

Figure 1 is a flow chart illustrating the analysis of a typical sample by XPS. A preliminary consultation

with the supplier of the sample should be used to ensure that the sample is supplied in the form most

[2]

appropriate for analysis. ISO 18117 explains the issues involved with prior handling by the supplier

and also gives information on the most suitable container for transportation. In this consideration, the

analyst should also identify any particular problems likely to arise. Table 1 provides a list of example

problems. Prior to any work, discussions should be held between the analyst and the customer to

gain as much information as possible by reviewing what is already known regarding the sample and

[2]

its history. In addition to the information listed in ISO 18117 , Table 2 indicates information that

will assist in deciding how to conduct the XPS analysis. Following these preliminary discussions,

the sample(s) may need to be prepared to allow mounting in the spectrometer and to reduce, where

[1]

possible, the subsequent analysis time. ISO 18116 provides details of how to do this. The analyst

will be responsible for the instrument characterization, which will include the calibration state and

the overall performance of the XPS instrument. A guide to calibration of the energy scale is given in

[14] [9] [18]

ISO 15472 . Checks for the intensity scale are given in ISO 24237 and ISO 21270 .

Once the specimen has been mounted in the spectrometer and the system pumped down, data

acquisition can commence. A wide scan should be obtained first and then analysed to determine the

[31]

elements present. ISO 16243 provides information on recording and reporting data in XPS. The wide-

scan spectrum can provide qualitative and semiquantitative information regarding composition and

the depth distribution of species. This may yield sufficient information to satisfy the customer and the

analysis may be terminated. However, in most cases, more data are required and narrow-scan spectra

will then be recorded from regions identified in the wide-scan spectrum. Analysis of these narrow-

scan spectra will provide chemical-state information, more accurate quantitative information and

near-surface depth information. At a later time in the investigation the wide scan should be repeated

to determine if there has been degradation (e.g. due to X-ray irradiation or to surface reactions with

ambient gases in the vacuum system). Following evaluation of the XPS data, the analyst should produce

a report.

2 © ISO 2019 – All rights reserved

---------------------- Page: 8 ----------------------

ISO 10810:2019(E)

Table 1 — Problems likely to arise and related ISO standards

Problem Example ISO standard

[1]

Outgassing Water vapour ISO 18116

Degradation Polymers and organics ISO 18554

[28]

Charging Insulators ISO 19318

Reduction Oxides

Contaminant mobility Chlorine

[1]

Sample containment Powders ISO 18116

Surface topography Fibres

Table 2 — Sample information and history

Sample information and history

Thermal

Contamination

Possible composition

Segregation

Surface layer

Homogeneous

Islands

© ISO 2019 – All rights reserved 3

---------------------- Page: 9 ----------------------

ISO 10810:2019(E)

NOTE The numbers in brackets indicate the respective subclauses in this document.

Figure 1 — Flow chart of an XPS analysis

6 Specimen characterization

6.1 General

The complexity of the interacting factors in XPS analyses arises from the many different forms of

specimen materials and the variety of material types that may be encountered as well as from the

different XPS experiments that might be required. Table 3 illustrates possible specimen forms, material

types, and XPS experiments or issues for further review. The analyst should also be aware that samples

can consist of multiple components and phases, and that identification of the components and phases

present (and their spatial arrangements) can be an important part of an XPS analysis. A further

complication is that non-conducting samples may charge.

4 © ISO 2019 – All rights reserved

---------------------- Page: 10 ----------------------

ISO 10810:2019(E)

Table 3 — Some specimen forms, material types, in situ specimen treatments

and possible XPS experiments

Specimen forms Material types In situ specimen treatments XPS experiments

Adsorbed layers (6.2.3) Alloy (6.3.2) Cooling (6.5.2) Angle-resolved XPS

Amorphous Biological (6.3.9) Degradation Small area analysis

Fibres (6.2.8) Catalyst (6.3.7) Deposit thin films Large area analysis

Films (6.2.3) Ceramic (6.3.6) Expose to high gas pressure Depth profile

(6.5.5)

Interface (6.2.4) Composite Fracture (6.5.3) Imaging

Internal interface (6.2.9) Glass (6.3.8) Heating (6.5.2) Line scan

Liquid Insulator (6.3.8) Insert into liquids (6.5.5)

Multilayered (6.2.4) Magnetic metal (6.3.5) Ion bombardment (6.5.4)

Nano-material Metal (6.3.2) Scraping (6.5.3)

Non-metal (pure)

Non-porous (6.2.5) element

Pattern system Polymer (6.3.3)

Polycrystal Semiconductor (6.3.4)

Porous (6.2.6)

Powder (6.2.7)

Residue (6.2.3)

Segregated layer (6.2.3)

Single crystal (6.2.2)

Solid

Semiconductor wafer Semiconductor Ozone and UV/ozone cleaning

Textile (6.2.8)

Contamination

6.2 Specimen forms

6.2.1 General

The form of the specimen to be analysed will strongly dictate the kinds of experimental approach that

can and need to be employed.

6.2.2 Single crystal

This type of sample should have a flat surface. Quantitative analyses will generally be difficult because

of anisotropies in the angular distributions of the photoemitted electrons due to electron diffraction

[3][4]

or to forward-focusing effects . These anisotropies are nevertheless useful in determining the

structural properties of the sample.

6.2.3 Adsorbed or segregated layers, films and residues

It should, in general, be possible to obtain a quantitative analysis and chemical-state information for

[5][6]

adsorbed or segregated layers, films and residues . If the substrate is a single crystal, however,

quantitative analyses will generally be difficult, but the angular distributions of the photoemitted

[3]

electrons can give useful structural information . Angle-resolved XPS (ARXPS), as described in 9.3.3,

will enable the layer thickness to be determined, provided the layer thickness does not exceed around

three times the effective attenuation length (EAL) of the substrate peak. This will be of progressively

lower accuracy for films above one EAL in thickness.

© ISO 2019 – All rights reserved 5

---------------------- Page: 11 ----------------------

ISO 10810:2019(E)

6.2.4 Interfaces and multilayered samples

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.