ISO 16129:2012

(Main)Surface chemical analysis — X-ray photoelectron spectroscopy — Procedures for assessing the day-to-day performance of an X-ray photoelectron spectrometer

Surface chemical analysis — X-ray photoelectron spectroscopy — Procedures for assessing the day-to-day performance of an X-ray photoelectron spectrometer

Analyse chimique des surfaces — Spectroscopie de photoélectrons X — Modes opératoires d'évaluation de la performance au jour le jour d'un spectromètre de photoélectrons X

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 16129

First edition

2012-04-15

Surface chemical analysis — X-ray

photoelectron spectroscopy — Procedures

for assessing the day-to-day performance

of an X-ray photoelectron spectrometer

Analyse chimique des surfaces — Spectroscopie de photoélectrons

X — Modes opératoires d’évaluation de la performance au jour le jour

d’un spectromètre de photoélectrons X

Reference number

ISO 16129:2012(E)

©

ISO 2012

---------------------- Page: 1 ----------------------

ISO 16129:2012(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2012

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or ISO’s

member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2012 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 16129:2012(E)

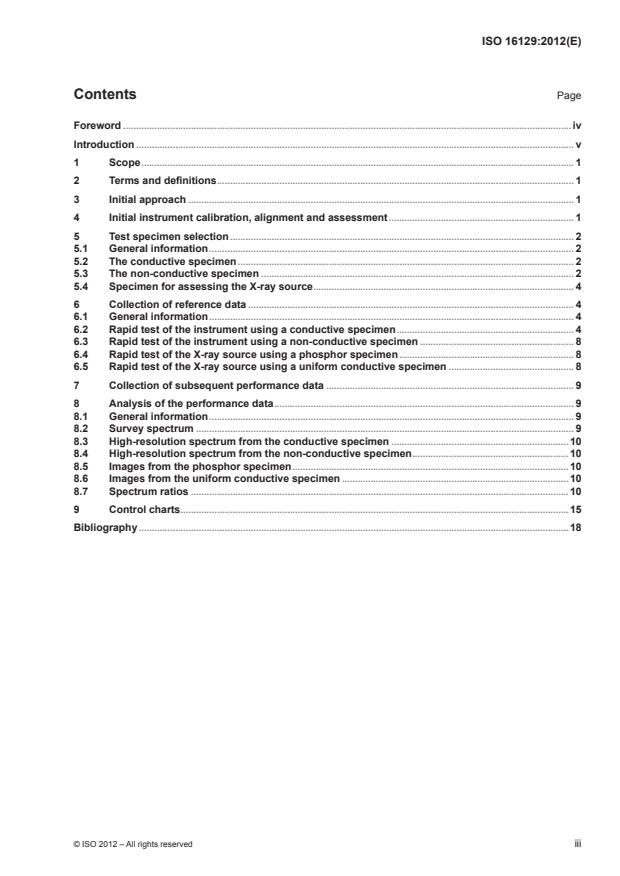

Contents Page

Foreword .iv

Introduction . v

1 Scope . 1

2 Terms and definitions . 1

3 Initial approach . 1

4 Initial instrument calibration, alignment and assessment . 1

5 Test specimen selection . 2

5.1 General information . 2

5.2 The conductive specimen . 2

5.3 The non-conductive specimen . 2

5.4 Specimen for assessing the X-ray source . 4

6 Collection of reference data . 4

6.1 General information . 4

6.2 Rapid test of the instrument using a conductive specimen . 4

6.3 Rapid test of the instrument using a non-conductive specimen . 8

6.4 Rapid test of the X-ray source using a phosphor specimen . 8

6.5 Rapid test of the X-ray source using a uniform conductive specimen . 8

7 Collection of subsequent performance data . 9

8 Analysis of the performance data . 9

8.1 General information . 9

8.2 Survey spectrum . 9

8.3 High-resolution spectrum from the conductive specimen .10

8.4 High-resolution spectrum from the non-conductive specimen .10

8.5 Images from the phosphor specimen .10

8.6 Images from the uniform conductive specimen .10

8.7 Spectrum ratios .10

9 Control charts .15

Bibliography .18

© ISO 2012 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 16129:2012(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the International

Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 16129 was prepared by Technical Committee ISO/TC 201, Surface chemical analysis, Subcommittee

SC 7, Electron spectroscopies.

iv © ISO 2012 – All rights reserved

---------------------- Page: 4 ----------------------

ISO 16129:2012(E)

Introduction

XPS instruments are complex, and unsatisfactory performance is not always obvious to an operator. It is

therefore necessary to provide a test for the correct operation of the system that can be performed regularly

and frequently without interfering excessively with the normal work of the laboratory.

A full diagnostic test can require many hours or even days; such a test can be appropriate only when the

instrument is known to have a fault that needs to be remedied or following a major maintenance procedure.

Data acquired before a problem is uncovered become suspect if the spectrometer has not been routinely

tested, leading to a loss of confidence in those data. If a regular check of the instrument is made, changes in

performance can be monitored and corrective action taken in good time to ensure that the data supplied are

fit-for-purpose. In the event that a serious fault is uncovered, then only the data since the last check can be in

doubt and need to be repeated.

The purpose of this document is to provide a user with a procedure which is not excessively time-consuming so

that it is capable of being completed on a regular and frequent basis, daily if required. The user will then gain an

awareness of the current characteristics of the instrument so that a decision can be made as to whether or not a

more complete and time-consuming action is required to return the instrument to a satisfactory level of performance.

This procedure is intended to be applied to an XPS instrument that has been correctly calibrated and aligned

in accordance with ISO standards or manufacturer’s instructions. It is designed to highlight aspects of the

instrument’s characteristics that differ significantly from those that were measured immediately following the

calibration procedure. The procedure does not show how the instrument can be returned to its original state.

Instead, it guides the user to possible areas of concern. The procedure provides data that can be used in control

charts, allowing trends to be observed and acted upon before data quality deteriorates to an unacceptable level

for the needs of the analyst.

© ISO 2012 – All rights reserved v

---------------------- Page: 5 ----------------------

INTERNATIONAL STANDARD ISO 16129:2012(E)

Surface chemical analysis — X-ray photoelectron

spectroscopy — Procedures for assessing the day-to-day

performance of an X-ray photoelectron spectrometer

1 Scope

This International Standard is designed to allow the user to assess, on a regular basis, several key parameters

of an X-ray photoelectron spectrometer. It is not intended to provide an exhaustive performance check, but

instead provides a rapid set of tests that can be conducted frequently. Aspects of instrument behaviour covered

by this International Standard include the vacuum, measurements of spectra of conductive or non-conductive

test specimens and the current state of the X-ray source. Other important aspects of the instrument performance

(e.g. lateral resolution) fall outside the scope of this International Standard. The standard is intended for use

with commercial X-ray photoelectron spectrometers equipped with a monochromated Al Kα X-ray source or

with an unmonochromated Al or Mg Kα X-ray source.

2 Terms and definitions

For definitions of the spectroscopy terms used in this International Standard, the reader is referred to

[10]

ISO 18115-1 .

The following abbreviations are used:

FWHM full width at half maximum

PET poly(ethylene terephthalate)

PTFE polytetrafluoroethylene

XPS X-ray photoelectron spectroscopy

3 Initial approach

Most instruments are fitted with a vacuum gauge or gauges. These shall be read frequently and the reasons for

large variations understood. A large increase in the pressure can be due to the properties of a test specimen inside

the instrument, a fault in the pumping system, an increase in the temperature of the vacuum system or a leak.

Similarly, most instruments have status indicators, either for the system as a whole or for sub-systems or

modules. Examples of such indicators include water flow rate, data system communications status and electrical

power. These can be visible as part of the instrument hardware itself or on screen through an instrument

control (data acquisition) system. Such indicators again shall be carefully monitored, along with any measured

values that are reported.

4 Initial instrument calibration, alignment and assessment

Before undertaking the procedure described in the following clauses, it is essential that the instrument be

calibrated and aligned to an optimum performance level. This is achieved by following the relevant International

Standards (References [5] to [9]) or the manufacturer’s instructions. Choose the two settings of the instrument

operating conditions that are needed to obtain survey spectra and high-resolution spectra. These should be

settings that you regularly use and will be described in Clause 6. Since this is a rapid check, only these two

settings are chosen, but these can show faults that are common to all settings. These settings shall always

be used in future checks unless they are later found to be less effective than other settings. If the designated

settings are changed, data at both the new and old settings shall be recorded at the time of change.

© ISO 2012 – All rights reserved 1

---------------------- Page: 6 ----------------------

ISO 16129:2012(E)

5 Test specimen selection

5.1 General information

Three types of test specimen are required for the full procedure described in this International Standard: a

conductive specimen, a non-conductive specimen and a specimen suitable for assessing the quality of the

X-ray beam (e.g. X-ray spot size, shape and uniformity). The conductive specimen provides information that

the basic energy and intensity calibrations of the instrument are consistent from day to day. When using a non-

monochromatic X-ray source having more than one anode material, the survey spectrum shall be examined to

check for peaks arising from specimen irradiation from the anode that is not currently being used (this is due

to “cross-talk” within the X-ray source). Similarly, when anode coatings wear, X-rays can be emitted from the

substrate material, which is often copper. The survey spectrum shall be examined for peaks arising from X-rays

produced from the substrate material. When using a magnesium anode, there can be peaks due to radiation

from O Kα arising from oxidation of the anode coating. These peaks are often called ghost peaks. Table 1

shows the approximate positions of commonly encountered ghost peaks when acquiring an XPS spectrum

from silver using Mg Kα radiation.

Table 1 — Examples of approximate positions, on the binding-energy scale, of frequently

encountered ghost peaks in a silver spectrum collected using a magnesium anode

(The photon energy of Mg Kα radiation is 1 253,6 eV)

Peak position on the

Radiation giving rise to Photon energy Possible origin of

binding-energy scale

ghost peaks eV radiation

eV

Al Kα 1 486,6 From second anode in a 135

twin anode source

O Kα 524,9 From oxide on the surface 1 097

of the magnesium anode.

Cu Lα 929,7 From anode substrate 692

The non-conductive specimen is required to confirm that the charge compensation system is operating

satisfactorily when non-conducting specimens are being analysed. The nature of the specimen that is required

for assessing the X-ray beam depends upon the type of instrument being used. If the analysis position is visible

during the normal operation of the instrument, the quality of the focus and the alignment of the X-ray beam from

a monochromated source can be assessed using a phosphor specimen. If the analysis position is not visible in

normal operation and the instrument is capable of imaging, a uniform (there should be no features visible in an

image of the specimen when the instrument is in its optimum condition), conductive specimen can be used; this

can be the conductive specimen mentioned above. All specimens used shall be large enough to completely fill

the defined analysis region of the spectrometer.

5.2 The conductive specimen

A suitable conductive specimen shall be selected. This should be a material that produces several peaks in the

photoelectron spectrum. Preferably, these peaks should be widely spaced in binding energy. The specimen

shall be one whose surface can be cleaned easily by sputtering with noble-gas ions.

A pure (≥ 99,8 %) specimen of silver foil is suitable for this measurement and is recommended. If, however, a

different material is commonly analysed in the user’s laboratory and conforms to the above criteria, this may

be used instead. For convenience, it is assumed here that silver has been selected as the conductive reference

material. The same conductive specimen shall be used for all measurements.

5.3 The non-conductive specimen

Non-conductive specimens, and conductive specimens with a non-conductive surface layer, charge under the

X-ray flux, resulting in shifts in the peak binding energies relative to the uncharged state.

2 © ISO 2012 – All rights reserved

---------------------- Page: 7 ----------------------

ISO 16129:2012(E)

Select a non-conductive material often studied in your laboratory, for which you have a good stock and which

is capable of being maintained with a surface in a reproducible state. If you are unsure of a material to use,

examples that have been found to be useful for tests of instrumental performance are shown in Table 2.

Examples are given with different forms. You might wish to select a specimen with a form similar to that of the

specimens most commonly analysed with the instrument. Care shall be taken to select a material which does

not exhibit degradation under the X-ray beam during the analysis.

Table 2 — Examples of non-conductive specimens that may be used for this procedure

Material Form Cleaning

PET Sheet or fibre Not required

Laboratory filter

Sheet Not required

paper

Poly(ethylene terephthalate) (PET) has long been used to evaluate both the energy resolution and the

effectiveness of charge control in XPS. It shows a structure of three C 1s peaks together with shake-up

intensity. The minimum between the peak at the lowest binding energy and the adjacent peak at a separation

of ~1,5 eV is highly sensitive to the combination of the instrumental resolution and the uniformity of the charge

correction. The ease of achieving suitable and consistent energy resolution will depend on both the operator

and the instrumental capability.

An example of the C 1s spectrum from PET is shown in Figure 1.

Y

9 000

8 000

7 000

6 000

5 000

4 000

3 000

2 000

1 000

0

X 294 292 290 288 286 284 282 280

Key

X binding energy (eV)

Y number of counts

Figure 1 — Example of a C 1s spectrum from PET

© ISO 2012 – All rights reserved 3

---------------------- Page: 8 ----------------------

ISO 16129:2012(E)

More recently, careful studies on cellulose-based materials (paper) have indicated that these are suitable

1)

materials for use in this test (see References [1] and [2]). It has been shown that laboratory filter paper

provides reproducible XPS spectra. If using paper, avoid releasing loose fibres into the instrument as they can

cause a deterioration in performance.

Alternatively, the specimen can be one with which the user is familiar. It shall be a material that provides a

reliably reproducible spectrum with little or no specimen preparation.

5.4 Specimen for assessing the X-ray source

A phosphor specimen is suitable for those instruments that are fitted with a monochromatic X-ray source and

in which the analysis position is visible, preferably with a microscope and camera. The phosphor specimen

should be as flat and uniform as possible and produce easily visible light under the X-ray bombardment.

Not all phosphor specimens are vacuum-compatible and not all phosphor materials are designed for optimum

excitation by X-rays. Ensure that a phosphor specimen of suitable quality is obtained from the supplier of the

2)

instrument or from another reputable supplier.

The uniform conductive specimen shall be used if an optical image of the analysis position is not available during

the normal operation of the instrument and the instrument is capable of producing X-ray-induced images. The

specimen shall be flat and of uniform composition over an area greater than the maximum area that is imaged

in the instrument. The silver specimen described in 5.2 would be suitable for this purpose.

6 Collection of reference data

6.1 General information

Once fully calibrated and functioning correctly at the designated settings described in Clause 4, the instrument

shall be used to collect a set of reference data. The specimens and the way in which data shall be collected are

described in this clause. If the spectrometer is routinely used for conductive specimens, follow the procedure

described in 6.2 regularly and that in 6.3 occasionally, whereas for instruments used mainly for insulating

specimens follow the procedure described in 6.3 regularly and that in 6.2 occasionally. The interpretation of

“regular” and “occasional” depends on the use of the instrument and its behaviour. If data are critical, “regular”

might need to be interpreted as daily. For modern instruments used daily in normal use, “regular” may be

interpreted as “an interval of one week” and “occasionally” as “a period of one month”, but it must be stressed

that the appropriate interval does depend on the instrument and its intended use. Document your reasons for

your choice of the intervals. The control charts of Clause 9 will also be useful in determining the frequency at

which checks should be made.

All electron optics have an optimum focal point. The specimens shall be at the common focal point of the

analyser, the ion gun (if used), the neutralizer (if used) and the X-ray source. If the spectrometer is equipped

with an X-ray source whose height above the specimen is adjustable, the X-ray source shall be in the same

position for each test.

6.2 Rapid test of the instrument using a conductive specimen

6.2.1 Specimen mounting and pre-treatment

Mount the specimen on an appropriate specimen holder. It is important that the specimen be in good electrical

contact with the specimen holder. Place the specimen in the optimum analysis position in the spectrometer.

1) A suitable type of filter paper is S&S 589 Blue Ribbon Ashless, which can be obtained from Whatman plc, Springfield Mill,

James Whatman Way, Maidstone, Kent, ME14 2LE, UK, or one of this company’s international distributors. This information

is given for the convenience of users of this International Standard and does not constitute an endorsement by ISO of this

product.

2) Suitable phosphor specimens can be obtained from a number of suppliers, including TMS Vacuum Components,

Unit 21 Stirling Road, Castleham Industrial Estate, Hastings, East Sussex, TN38 9NP, UK. This information is given for the

convenience of users of this International Standard and does not constitute an endorsement by ISO of this supplier.

4 © ISO 2012 – All rights reserved

---------------------- Page: 9 ----------------------

ISO 16129:2012(E)

Take care to follow the manufacturer’s recommendations for positioning the specimen at the focal point, or use

whatever documented procedure is required for analysis. Ensure that all specimen stage parameters (X, Y, Z,

rotation and tilt) are correctly set.

If the instrument is fitted with a noble-gas ion gun, the specimen surface shall be cleaned by ion etching,

using conditions commonly found to be successful for this purpose and which remove a minimum amount of

2

material. A typical sputtering fluence for cleaning silver is 20 A⋅s/m . A typical value for the ion energy is 3 keV.

Excessive sputtering leads to significant roughening of the specimen so that it needs frequent replacement.

6.2.2 Survey spectrum

A survey or wide-scan spectrum shall be collected over the binding-energy range from −10 eV to a value within

50 eV of the value of the photon energy used to irradiate the specimen (e.g. a binding energy of 1 437 eV

for Al Kα X-rays) or to whatever maximum range is available. The analyser shall be operated in the constant

analyser energy (CAE) mode. The data shall be collected in energy steps no wider than 0,5 eV. The dwell time

5

at each energy step shall be sufficient to collect at least 10 counts in at least one energy channel in an XPS

peak. In the case of silver, this will be the Ag 3d peak at ~368 eV binding energy. Bear in mind that it is the

5/2

number of counts that is important here, not the count rate. The acquisition time depends upon the sensitivity of

5

the instrument, so the minimum dwell time per channel is given by 10 counts divided by the signal strength in

counts per second. On modern instruments, such a spectrum will be collected in a few minutes. Care shall be

taken to avoid selecting conditions that would result in count rates that are high enough to induce nonlinearity

in the detector.

The pass energy of the analyser used for this spectrum should be the same as that typically used for a survey

spectrum. If using monochromatic Al Kα X-rays, it is likely that the pass energy chosen would result in a full

width at half-maximum (FWHM) amplitude of between 1,5 eV and 2,5 eV for the Ag 3d peak from a clean

5/2

silver foil. If using non-monochromatic Al or Mg Kα X-rays, it is likely that the pass energy chosen would result

in an FWHM of between 1,5 eV and 3,0 eV.

The anode power in the X-ray source should be the same as that typically used for analysis.

Once collected, the spectrum shall be examined, first to ensure that there is a tolerably low level of detectable

contamination present on the surface. The presence of a significant quantity of adventitious carbon indicates

that the surface is contaminated. The height of the peak due to C 1s should be less than 1 % of the height of

the peak due to Ag 3d . If the carbon peak is too intense, the cleaning procedure shall be repeated and the

5/2

spectrum collected again. Such a spectrum is shown in Figure 2. In this spectrum, the FWHM of the Ag 3d

5/2

peak is 2,4 eV.

© ISO 2012 – All rights reserved 5

---------------------- Page: 10 ----------------------

ISO 16129:2012(E)

Y

140

120

100

80

60

40

20

0

X 1 390 1 190 990 790 590 390 190 -10

Key

X binding energy (eV)

Y kcounts

Figure 2 — An example of a survey spectrum from a clean silver specimen to be used as a reference

(The spectrum was collected using Al Kα radiaton from an X-ray monochromator)

The survey spectrum shall be examined and the following data recorded to provide reference values for

control charts:

a) The number of counts in the channel having the greatest number of counts.

b) The energy position of the channel having the greatest number of counts on the binding-energy scale.

c) The FWHM amplitude of the Ag 3d peak.

5/2

d) The average number of counts per channel in a background region of the spectrum. For example, the

range could be from 450 eV to 460 eV. This range includes the inelastic tail from the Ag 3d peaks and so

the background is relatively high, allowing greater precision in the measurement of the number of counts.

e) The total number of counts in all channels in the binding-energy range from –5 eV to –10 eV.

f) The intensity of any ghost peaks present. This is only required if a non-monochromatic X-ray source

is being used.

It is not necessary to include the intensity of the C 1s peak in a control chart, but the height of the C 1s peak above its

local background shall be noted as it provides a record of the state of the specimen at the time of the measurement.

When measuring the background intensity from a spectrum produced using a non-monochromatic source,

care shall be taken to avoid those areas of the spectrum in which ghost or satellite peaks might be present.

6.2.3 High-resolution spectrum

A high-resolution or narrow-scan spectrum shall then be recorded of the Ag 3d peak. At a minimum, this

5/2

spectrum shall be recorded over the binding-energy range from 365 eV to 372 eV. The spectrum shall be

collected with an energy step size not larger than 0,05 eV and the dwell time shall be such that there are at

4

least 10 counts in the channel containing the greatest number of counts. The acquisition time will depend

6 © ISO 2012 – All rights reserved

---------------------- Page: 11 ----------------------

ISO 16129:2012(E)

4

upon the sensitivity of the instrument, so the minimum dwell time per channel is given by 10 counts divided by

the signal strength in counts per second. For this spectrum, the pass energy of the analyser should be set to a

value normally used by the analyst for the collection of high-resolution spectra. It is anticipated that the FWHM

of the Ag 3d peak will be in the range 0,55 eV to 0,65 eV if an X-ray monochromator is used and between

5/2

0,8 eV to 1,0 eV if a monochromator is not used. Figure 3 shows an example of such a spectrum.

Y

160

140

120

100

80

60

40

20

0

X 371 370 369 368 367 366 365

Key

X binding energy (eV)

Y kcounts

Figure 3 — High-resolution Ag 3d spectrum from clean silver using Al Kα radiaton from an X‑ray

5/2

monochromator

Once collected, the spectrum shall be examined and the following parameters recorded:

a) The maximum peak height after subtraction of a suitable background (often a Shirley background).

b) The ratio of the intensity of this peak to the intensity of the same peak in the survey spectrum.

c) The peak energy in the binding-energy scale (peak fitting could be used to determine this parameter).

d) The FWHM of the peak above the background chosen.

e) The signal-to-background ratio, defined as the number of counts in the peak maximum divided by the

average number of counts in a range of channels remote from the peak. In Figure 3, a suitable range would

be those channels between 365,5 eV and 366,5 eV binding energy.

These measurements will be used as reference values in control charts

© ISO 2012 – All rights reserved 7

---------------------- Page: 12 ----------------------

ISO 16129:2012(E)

6.3 Rapid test of the instrument using a non-conductive specimen

6.3.1 Specimen mounting and positioning

Mount and position the specimen in the spectrometer as described for the conductive specimen in 6.2.1. If

cleaning with an ion beam is appropriate for the specimen type chosen, sputter the specimen using conditions

that have been proved to be effective.

6.3.2 High-resolution spectrum

A high-resolution spectrum shall be recorded over a representative peak in this spectrum. If the specimen

is organic in nature, this is likely to be the C 1s peak. The scan range for the spectrum shall be

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.